Table of Contents

Toggle- What Is an Industrial Motor Starter?

- The Safety Challenges in Industrial Motor Control

- Motor Starter Protection Mechanisms Explained

- Types of Motor Starters and Their Safety Profiles

- Best Practices for Motor Starter Safety & Selection

- Standards, Compliance, and Industrial Safety Codes

- Real-World Example: When Motor Starter Safety Prevents Disaster

- Future Trends: Smart Protection & Predictive Maintenance

- Conclusion

In an industrial setting, electric motors are the unsung heroes powering conveyor belts, pumps, fans, compressors, and critical equipment day in and day out. But what happens when those motors start too suddenly, pull too much current, or fail unexpectedly?

The result isn’t just mechanical wear—it’s a real safety risk.

That’s where motor starters come in. Far more than simple “on/off” switches, industrial motor starters are engineered for control, protection, and reliability. When selected and installed correctly, they prevent overloads, shut down safely during power failures, and reduce stress on both motors and operators.

In other words, motor starter safety is not just about protecting machines—it’s about protecting people.

In this guide, we’ll walk you through:

- How industrial motor starters work

- What protection mechanisms do they provide?

- The safety challenges they help mitigate

- Best practices for selecting, sizing, and maintaining them

- And how evolving technologies are reshaping motor starter safety

Whether you’re an integrator managing dozens of projects or a facility manager battling daily wear and tear on aging systems, understanding motor starter protection is crucial to maintaining a safe, efficient, and compliant operation.

What Is an Industrial Motor Starter?

Let’s start simple: A motor starter is an electrical device used to start, stop, and protect electric motors. In industrial environments, where motors can be large, expensive, and essential to operations, starters serve as gatekeepers—regulating how motors receive power and how they respond when something goes wrong.

Most industrial motor starters include three key functions:

- Controlling when a motor starts and stops

- Protecting the motor from overloads and faults

- Safeguarding against unexpected restarts or dangerous surges

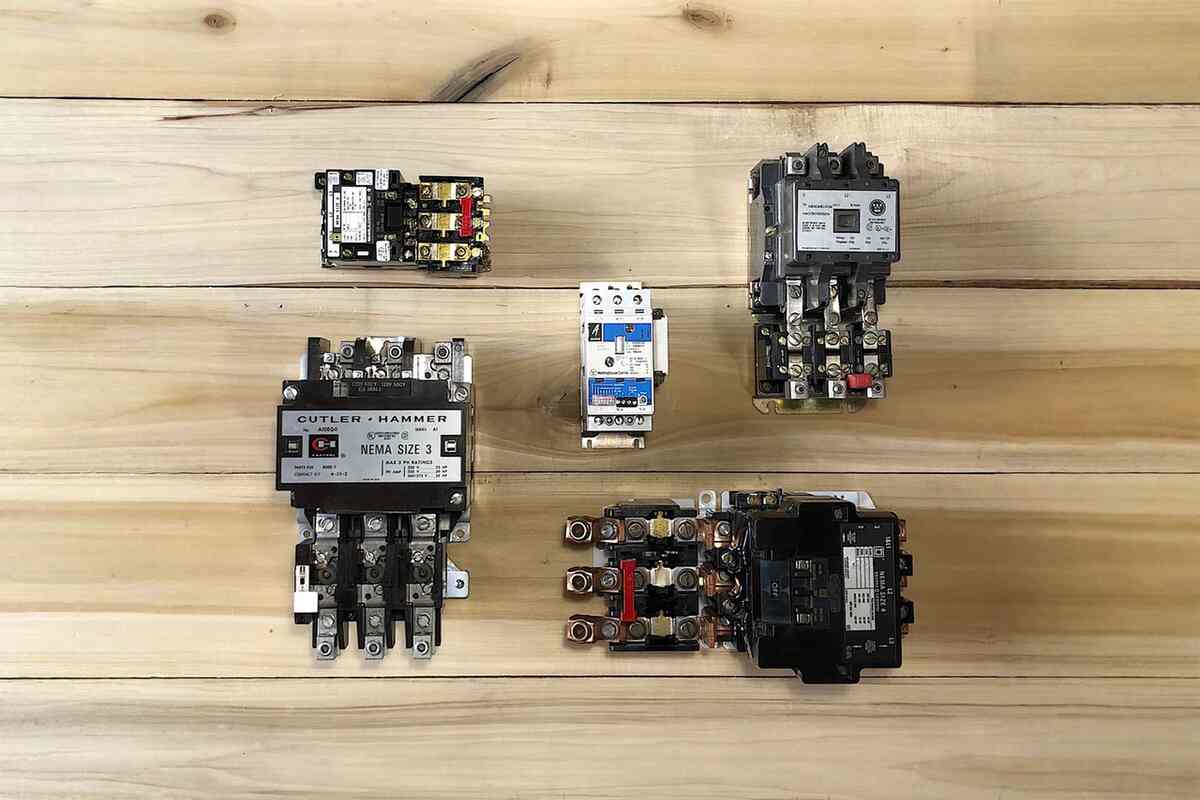

Components of a Typical Motor Starter

At its core, a starter typically includes:

- Contactor – Electrically controls the power flow to the motor

- Overload Relay – Detects current beyond safe limits and interrupts the circuit

- Control Circuit – Handles the start/stop logic, often with safety interlocks or remote activation

In more advanced designs, you’ll also find:

- Phase-loss protection,

- Soft-start technology,

- or smart diagnostics that anticipate failure before it happens.

Motor Starter vs Contactor vs VFD: What’s the Difference?

A quick clarification:

- A contactor is just a switching device—it doesn’t protect.

- A starter includes both the contactor and protective mechanisms.

- A VFD (variable frequency drive) controls motor speed and torque, often with some built-in protection, but it’s a different class of device entirely.

If you’re managing high-horsepower motors or critical systems, relying on a contactor alone is like driving a semi-truck with bicycle brakes. Industrial motor starters are built for protection, not just operation.

The Safety Challenges in Industrial Motor Control

Before we can appreciate what a motor starter protects us from, it’s important to understand what can go wrong without one. Industrial environments are inherently high-risk—lots of power, complex machinery, demanding timelines. It doesn’t take much for something small to become something serious.

Here are the most common safety challenges motor starters are designed to address—and why ignoring them can cost you more than downtime.

Overloads That Go Unnoticed

Industrial motors often run for hours (or days) under high loads. If the motor draws more current than it’s rated for—even slightly—for a sustained period, it can overheat. Overheating shortens the motor’s lifespan and can eventually lead to failure, smoke, fire, or even arc flash events in extreme cases.

Without a properly sized starter equipped with overload protection, this danger can fly under the radar until it’s too late.

Hazardous Restarts After Power Loss

Ever had power flicker back on after an outage? Imagine a massive motor unexpectedly re-engaging with full torque the moment the electricity returns. That’s not just dangerous for your equipment—it’s dangerous for anyone nearby.

One of the critical features of motor starter safety is the no-voltage release or anti-restart mechanism. This ensures that motors don’t automatically restart after a power failure, helping prevent injuries, mechanical damage, or worse.

Short Circuits and Fault Currents

Industrial motors operate at high voltages and currents. A short circuit—whether due to a wiring issue, insulation breakdown, or equipment fault—can cause catastrophic damage in milliseconds. Starters coordinated with circuit breakers or fuses help isolate the motor immediately, reducing the risk of fire and equipment loss.

More importantly, they provide personnel protection from contact with energized, faulted systems.

Phase Loss or Imbalance

Three-phase motors are the norm in industrial setups. But if one phase drops out or becomes imbalanced (which happens more than we like to admit), motors can overheat or run erratically—without obvious signs. This often leads to “burnt windings” or an entire motor winding up in a dumpster.

Many industrial motor starters are equipped with phase-monitoring features to trip safely when something’s off.

Personnel Risk from Manual Workarounds

In the absence of proper motor control and protection, operators often resort to risky workarounds—like manually bypassing starter logic or resetting trips without investigating the cause.

This isn’t just bad practice—it puts people in danger.

A good motor starter design removes that temptation by embedding the safety features directly into the control process. That means fewer risks, fewer bad decisions under pressure.

The Bottom Line?

Every motor starter is a safety device first, and a control device second.

Whether it’s preventing an overload, stopping a hazardous restart, or signaling a bigger issue upstream, the right starter doesn’t just keep your system running—it keeps your people protected.

Motor Starter Protection Mechanisms Explained

If you’ve ever watched a motor fail mid-process, you know how fast things can spiral. A tripped breaker, scorched wires, or worse—complete shutdown of your operation. But here’s the thing: most of those failures don’t happen out of nowhere. They were preventable.

That’s the value of a well-designed motor starter. Protection is not a feature—it’s the entire point.

Let’s break down the essential safety mechanisms baked into modern motor starters, and how each one helps shield your people, your equipment, and your uptime.

Overload Protection

What it does:

Monitors the motor’s current draw and trips if it exceeds a safe level for too long.

Why it matters:

Motors can run “hot” for hours without showing visible signs. Thermal overload relays—whether bi-metallic or electronic—act like watchdogs, detecting when current draw drifts into unsafe territory due to mechanical jams, voltage drops, or other issues.

How it protects you:

- Prevents overheating and motor burnout

- Reduces risk of fire or internal arcing

- Gives clear trip indication to avoid “silent” faults

Bonus tip: Many modern overloads include reset delay timers or manual reset modes to ensure safety checks are done before re-engaging.

Short Circuit Protection

What it does:

Works in coordination with circuit breakers or fuses to interrupt high-current faults immediately.

Why it matters:

A short circuit can create an explosive fault within milliseconds. While starters aren’t designed to clear these faults themselves, they’re part of a coordinated system where protection is layered—starter + breaker = system protection.

How it protects you:

- Limits the energy released during a fault

- Prevents catastrophic damage to the motor and starter

- Safeguards nearby personnel from electric shock or arc flash

No-Voltage Release (Anti-Restart)

What it does:

Prevents a motor from automatically restarting after a power outage unless manually reset.

Why it matters:

A sudden restart after a blackout can send a piece of equipment into motion when nobody’s expecting it. This is one of the most common—and dangerous—failure points in facilities that don’t use proper starters.

How it protects you:

- Stops unintentional equipment movement

- Protects workers during reset and recovery

- Complies with OSHA and other safety codes

Phase Loss and Phase Imbalance Detection

What it does:

Trips the starter if one of the three power phases is lost or significantly weaker.

Why it matters:

Running a three-phase motor on two phases will fry it fast. But motors don’t always “scream” when they’re in trouble—they just quietly degrade until they die. Starters with phase monitoring can detect this condition and disconnect power before damage happens.

How it protects you:

- Prevents uneven wear and overheating

- Avoids long-term electrical degradation

- Flags issues upstream, like blown fuses or transformer faults

Emergency Stop & Lockout Integration

What it does:

Integrates the starter into your plant’s emergency systems and lockout/tagout (LOTO) procedures.

Why it matters:

Safety isn’t just automatic—it’s procedural. Starters should be compatible with e-stop circuits and manual disconnects to ensure equipment can be safely shut down for maintenance.

How it protects you:

- Enables safe shutdowns during emergencies

- Ensures maintenance personnel are protected from accidental re-energization

- Supports regulatory compliance and audit readiness

Environmental Protection (IP Ratings & Enclosures)

What it does:

Protects the starter itself from dust, water, oil, and corrosive atmospheres.

Why it matters:

A motor starter that fails due to contamination is a protection mechanism that’s not protecting anything. IP-rated enclosures and proper environmental sealing ensure the starter continues working under harsh conditions.

How it protects you:

- Keeps internal components dry, dust-free, and operational

- Maintains protection mechanisms in wet or hazardous areas

- Reduces maintenance frequency and unplanned repairs

Bonus: Diagnostic Feedback & Smart Features

Modern motor starters—especially soft starters and digital versions—may include:

- LED indicators for fault diagnostics

- Event logging

- Communication interfaces (Modbus, Ethernet/IP)

- Real-time monitoring of temperature, load, and runtime

These features make it easier for operators to spot issues before they lead to downtime or danger.

Motor starter protection isn’t about reacting to problems—it’s about preventing them in the first place. With the right safety mechanisms in place, you don’t just protect the motor. You protect your team, your timeline, and your reputation.

Types of Motor Starters and Their Safety Profiles

There’s no such thing as a “one-size-fits-all” motor starter. Industrial environments vary wildly—what’s safe and effective for a 3HP conveyor might be a disaster for a 75HP pump. That’s why understanding the different types of industrial motor starters is essential for ensuring both performance and protection.

Each type offers a unique safety profile. The wrong choice could lead to nuisance tripping, excessive wear, or even hazardous conditions. The right one? It becomes a silent safety partner you can trust.

Let’s walk through the most common starter types and what they mean for motor starter safety.

1. Direct-On-Line (DOL) Starters

What it is:

Simplest form of starter. Applies full voltage directly to the motor terminals.

Where it’s used:

Small motors (usually <5HP), low-inertia loads, where starting torque isn’t critical.

Safety Profile:

- Pros:

- Simple to install and maintain

- Includes basic overload protection

- Inexpensive option for small motors

- Simple to install and maintain

- Cons:

- High inrush current (6–8x motor rating) can cause mechanical shock

- May lead to electrical disturbances or nuisance tripping

- Not suitable for high-power motors due to start-up stress

- High inrush current (6–8x motor rating) can cause mechanical shock

Bottom line:

Safe for basic applications, but risky for large loads or sensitive systems.

2. Star-Delta Starters

What it is:

Starts the motor with reduced voltage (star connection), then switches to full power (delta connection) once up to speed.

Where it’s used:

Medium to large motors where the torque at startup can damage equipment.

Safety Profile:

- Pros:

- Reduces inrush current and starting torque

- Better protection for mechanical systems

- Reduces inrush current and starting torque

- Cons:

- Complex wiring and control logic

- Delay in switching can cause voltage dips or transient spikes

- Doesn’t provide advanced protection beyond overload trip

- Complex wiring and control logic

Bottom line:

A solid middle-ground option—reduces startup stress, but still needs careful setup to avoid issues.

3. Soft Starters

What it is:

Uses solid-state components to ramp voltage up (and down) gradually during start/stop.

Where it’s used:

Systems with belts, pumps, compressors—where mechanical shock must be minimized.

Safety Profile:

- Pros:

- Smooth acceleration = less wear on mechanical and electrical components

- Built-in overload and under-voltage protection

- Adjustable parameters for custom applications

- Smooth acceleration = less wear on mechanical and electrical components

- Cons:

- More expensive than DOL or star-delta

- Doesn’t regulate speed like a VFD

- May still require external short-circuit protection

- More expensive than DOL or star-delta

Bottom line:

Excellent for motor starter safety where equipment life and process stability matter. Great for reducing the “wear and tear” safety risks.

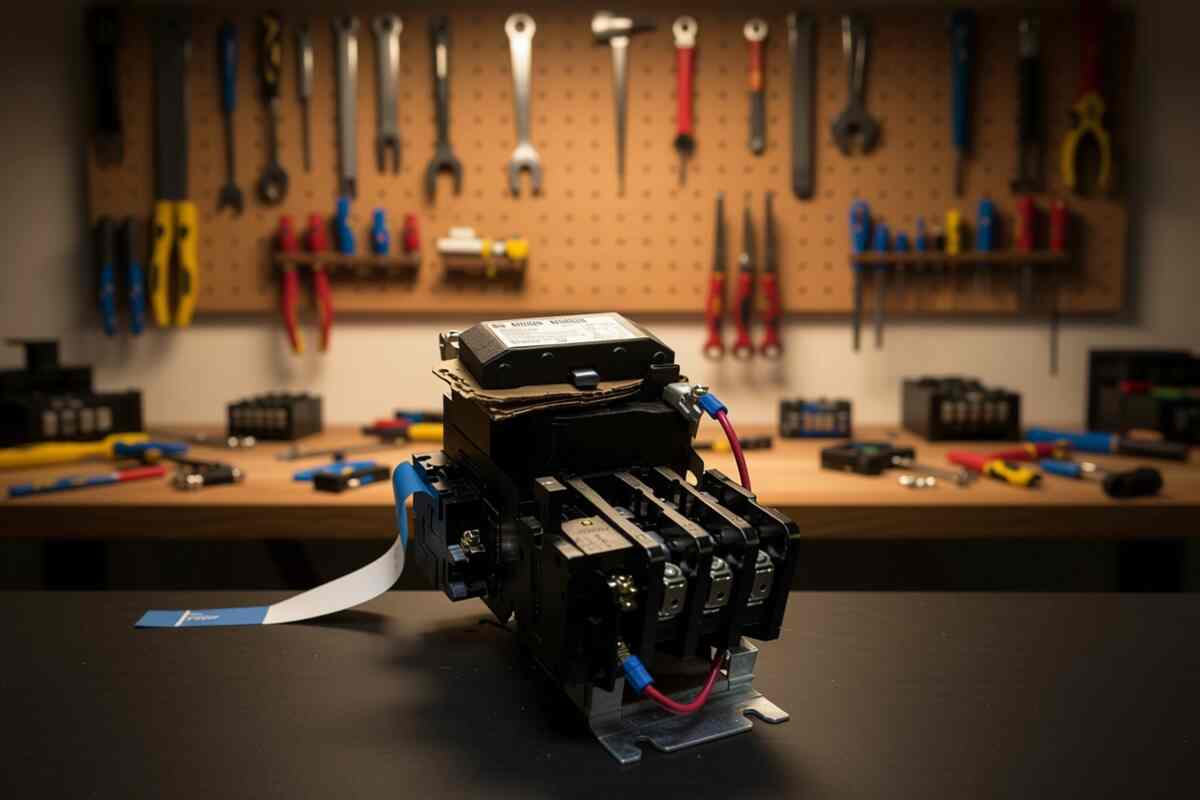

4. Magnetic Starters

What it is:

An electromechanical device with a contactor and overload relay, often integrated into control panels.

Where it’s used:

General-purpose industrial applications, often combined with manual switches or automated controls.

Safety Profile:

- Pros:

- Provides reliable motor starter protection (overload + anti-restart)

- Available with built-in safety interlocks and emergency stop integration

- Simple diagnostics with visual indicators or trip flags

- Provides reliable motor starter protection (overload + anti-restart)

- Cons:

- Limited to binary operation (start/stop)

- Not ideal for torque-sensitive or high-efficiency needs

- Limited to binary operation (start/stop)

Bottom line:

The backbone of industrial safety for decades—rugged, reliable, and highly dependable for most standard motor control setups.

5. Smart / Digital Starters

What it is:

Advanced motor starters with digital controls, communication interfaces, and diagnostics.

Where it’s used:

Modern plants focus on predictive maintenance, data-driven decisions, and IoT integration.

Safety Profile:

- Pros:

- Real-time monitoring of current, temperature, and voltage imbalance

- Event logs and fault history for troubleshooting

- Can be integrated into building/facility management systems

- Real-time monitoring of current, temperature, and voltage imbalance

- Cons:

- Higher upfront cost

- May require trained personnel for setup and interpretation

- Depends on consistent network/data integrity

- Higher upfront cost

Bottom line:

An ideal choice for industrial motor starter protection in digitally mature environments. Offers next-level safety through insight and automation.

Safety Isn’t Optional — It’s Built In

Each of these starters brings something different to the table. The safest choice? The one that fits your load, your process, your environment, and your team.

When you combine correct starter selection with proper motor starter protection mechanisms, you don’t just avoid failure. You design safety into the system—from day one.

Best Practices for Motor Starter Safety & Selection

A motor starter isn’t just another component on your bill of materials—it’s a critical safety gatekeeper. But to truly get the protection it’s designed to offer, you have to choose it, size it, and maintain it correctly.

Here are the most important best practices every electrical contractor, system integrator, or facility manager should follow to ensure maximum motor starter safety.

1. Start with the Load

Understand the motor and application:

- What’s the full-load current (FLC)?

- What kind of load is it driving—constant torque, variable torque, high inertia?

- How often will it start/stop during the day?

Why it matters:

Undersized starters may trip too soon—or worse, fail to protect during a true overload. Oversized starters may delay tripping until after damage has already occurred.

Tip: Always consult the motor nameplate and use manufacturer-specific sizing tables.

2. Choose the Right Starter Type

Reference the starter types we covered in Section 4. Ask yourself:

- Do you need to reduce mechanical stress at startup? → Use a soft starter

- Is the motor small and simple? → DOL might work

- Want diagnostics and network integration? → Go digital/smart

Why it matters:

A great safety system starts with the right foundation. Using a basic starter for a high-horsepower motor with a delicate load is like putting bicycle brakes on a freight train.

3. Correctly Set Overload Protection

Each overload relay must be set to match the motor’s full-load current, with consideration for ambient temperature and duty cycle.

Why it matters:

- If set too low → constant nuisance trips

- If set too high → delayed trip = overheated windings = motor failure

- If ignored → your “safety” device is just decoration

Pro tip: Periodically test and recalibrate your overload relays during preventive maintenance routines.

4. Match to the Environment

Consider the conditions where the starter will operate:

- Is it in a dusty or humid area?

- Is there exposure to oil, vibration, or corrosive gases?

- Will operators need to access it regularly?

Choose starters with the appropriate NEMA or IP-rated enclosures, and mount them in accessible, well-ventilated areas.

5. Integrate Emergency Stop and Lockout Protocols

Safety isn’t complete until it’s procedural.

Ensure your motor starter panel:

- Integrates with e-stop buttons in logical locations

- Supports manual lockout/tagout (LOTO) systems

- Can be clearly labeled and isolated for maintenance

Why it matters:

Even the best protection circuitry can’t prevent a hazard if the technician doesn’t have a safe way to shut it off.

6. Don’t Set It and Forget It: Maintain It

Too many facilities assume that once a starter is installed, it’s good forever.

Instead, implement routine inspections:

- Clean dust and debris from vents and terminals

- Check for contact wear or signs of overheating

- Test trip functions manually if possible

- Log any faults or resets and investigate root causes

“If your starter trips, it’s trying to tell you something. Don’t just reset—listen.”

7. Use Coordination Studies in Larger Systems

In plants with multiple starters, motors, and breakers, it’s critical that the protection system is selective—only the affected motor should trip in a fault, not the whole line.

Work with a professional to perform a coordination study, ensuring:

- Trip curves are layered appropriately

- Upstream/downstream devices work together

- Safety and uptime are both maximized

Bottom Line: Safety Comes from Strategy

Motor starter safety isn’t just about picking the right hardware—it’s about:

- Matching it to the load and conditions

- Setting it up the right way

- Maintaining it like it matters

- And treating it as a critical part of your safety culture

When done right, a properly chosen and maintained motor starter is a silent guardian of your systems—working quietly in the background to prevent problems before they happen.

Standards, Compliance, and Industrial Safety Codes

In industrial environments, safety isn’t optional—it’s mandated. And motor starters? They sit at the intersection of code compliance, equipment reliability, and personnel protection.

Let’s break down how motor starter protection ties directly into the standards and regulations your team is expected to follow—and what it takes to stay compliant.

OSHA (Occupational Safety and Health Administration – U.S.)

What it requires:

OSHA doesn’t spell out every electrical component, but it holds employers responsible for maintaining a safe working environment. This includes proper installation, maintenance, and operation of electrical equipment like starters.

Why it matters:

- Failure to use appropriate motor control and protection can result in violations under OSHA’s General Duty Clause.

- Improper lockout/tagout integration in starter circuits is a common citation.

“A non-compliant starter isn’t just a hazard—it’s a liability.”

NFPA 70E – Electrical Safety in the Workplace

What it covers:

NFPA 70E outlines practices for reducing electrical hazards. It’s your go-to for arc flash prevention, safe work zones, and PPE requirements—but it also highlights proper use of protective devices.

Motor starter safety relevance:

- Must prevent unexpected motor startup

- Should be compatible with energy isolation (LOTO)

- Arc energy reduction = starter coordination with breakers and fuses

- Labels and hazard warning signs are often applied to starter panels

Bottom line:

A well-integrated starter is part of your arc flash and energy isolation strategy.

NEC / NFPA 70 – National Electrical Code (U.S.)

Key Sections to Know:

- Article 430: Motors, Motor Circuits, and Controllers

- Article 409: Industrial Control Panels

- Article 110: General Requirements for Electrical Installations

Starter-related rules include:

- Required overload protection for motors

- Disconnecting means near the motor

- Short-circuit and ground-fault protection sizing

- Marking and identification of control devices

NEC = design foundation. Your industrial motor starter must meet these minimums, or it shouldn’t be in your panel.

IEC vs. NEMA: What’s the Difference, and Why Should You Care?

When you’re selecting a motor starter, you’ll likely come across two familiar acronyms: IEC and NEMA. These aren’t brands or product names—they’re two different standards that influence how starters are designed, rated, and built.

Think of them as two schools of thought on how to build reliable, safe electrical components.

IEC (International Electrotechnical Commission)

IEC starters are more common outside the U.S. and are known for being:

- Compact

- Modular

- Precision-rated for exact applications

They’re designed to do exactly what’s needed, with less “extra.” That makes them efficient and cost-effective, especially for systems where space is tight and every component is selected for its specific duty.

In short: You get what you need—no more, no less.

NEMA (National Electrical Manufacturers Association)

NEMA starters are typically found in U.S.-based systems and are built like tanks.

They’re:

- Overbuilt by design

- Larger and heavier

- Rated for longer life across a wide range of conditions

They can handle voltage fluctuations, high ambient temperatures, and general industrial abuse without blinking. NEMA standards are a favorite for durability, even if they cost more and take up more panel space.

In short: You get extra capacity and longer life—whether you need it or not.

Real-World Example: When Motor Starter Safety Prevents Disaster

Let’s be honest—motor starters don’t usually get the spotlight. Most days, they sit inside a panel, doing their job silently. But every now and then, one earns its keep.

Here’s a real-world scenario that shows exactly why motor starter protection isn’t just a technical detail—it’s a difference-maker between downtime and disaster.

The Setup: A Critical Conveyor System at a Food Processing Plant

The plant runs 24/7, pushing thousands of pounds of perishable product through an automated system. At the center of it all is a 40HP motor powering a long conveyor belt that links three major production lines.

Downtime? Not an option.

They were using an older magnetic starter—functional, but basic. No diagnostics. No ramp-up. Minimal protection beyond thermal overload.

The Problem: Mechanical Jam, Electrical Overload

One night, a small piece of packaging lodged itself in the conveyor’s drive mechanism. The motor kept pulling power, trying to push through the jam. No one noticed—yet.

Without proper trip settings or monitoring, the starter didn’t cut power in time. The motor overheated. The insulation broke down. Smoke followed. Then a full line shutdown.

Production stopped for 9 hours. Inventory spoiled. Emergency repairs, overtime, and safety incident report. It was avoidable.

The Fix: Smart Starter with Integrated Protection

After the incident, the facility manager upgraded to a smart soft starter with:

- Adjustable overload protection

- Current monitoring

- Diagnostic alerts to the maintenance team

- An emergency shutdown link to the building’s safety system

Months later, when a similar jam happened?

The system shut the motor down within seconds. An alert pinged the technician’s tablet. Zero downtime. Zero damage. No one even noticed—except the guy clearing the jam.

The Takeaway

A motor starter did that.

Not a redesign. Not a massive control system upgrade. Just the right industrial motor starter, installed with safety in mind.

Ask Yourself:

- Are your motor starters sized correctly?

- Do they trip when they should—or when it’s too late?

- Can your team diagnose faults quickly?

- Are you relying on outdated components that “usually work fine”?

Motor starter safety isn’t just about meeting code—it’s about avoiding moments like these altogether.

Future Trends: Smart Protection & Predictive Maintenance

Motor starters are evolving.

For decades, they’ve been hardwired, binary, and mostly reactive—flip the switch, trip on fault, call it a day. But as industrial operations become more connected, data-driven, and uptime-sensitive, motor starter protection is getting smarter.

Here’s where things are headed—and why it matters.

1. Built-In Diagnostics: Seeing the Fault Before It Happens

Modern smart motor starters aren’t just switches. They’re sensors. They monitor:

- Load current

- Voltage drops

- Phase imbalance

- Ambient temperature

- Number of starts per hour

Instead of just tripping and leaving the rest to guesswork, they log what happened, when, and why. This makes root-cause analysis faster and decisions easier.

2. Real-Time Alerts and Remote Monitoring

More starters now come with communication interfaces—Modbus, Ethernet/IP, PROFINET—so they can talk to your SCADA system, PLC, or even your phone.

This enables:

- Remote start/stop control

- Fault notifications to maintenance staff

- Integration into facility dashboards

Why it matters for safety:

You don’t have to wait for someone to “notice a smell” or “hear a weird noise.” You get early warnings before small problems escalate.

3. Soft Start + Soft Stop = Mechanical Peace of Mind

Advanced soft starters don’t just ramp voltage up—they control how the motor winds down too. This prevents:

- Sudden stops that damage belts, gears, or the product

- Water hammer in pump systems

- Backspin or rebound in conveyor systems

It’s not just about electrical protection anymore—it’s about protecting everything connected to the motor.

4. Predictive Maintenance & Health Scoring

Some smart starters use algorithms to track motor “wear” over time based on:

- Start/stop frequency

- Operating temperature trends

- Peak current draw

- Environmental conditions

They generate health scores, alerting you when it’s time to service a motor before it becomes a hazard or a headache.

This trend aligns directly with the shift toward reliability-centered maintenance (RCM) in modern industrial facilities.

5. Cloud Connectivity and IoT Integration

The most advanced starters connect to the cloud, allowing you to:

- View starter status from anywhere

- Receive email or SMS alerts

- Analyze data across multiple facilities

- Benchmark performance across similar systems

Yes—motor starter safety is now part of the Internet of Things (IoT).

While not every plant is ready to leap into cloud-connected control panels, the industry is clearly moving that way—and your next motor starter upgrade could set the foundation for it.

What This Means for Your Facility

As these technologies become more accessible, they’re changing the expectations around:

- How quickly you respond to faults

- How safely your motors operate

- How much control your team has—on-site or remotely

You don’t need to overhaul your entire system to benefit. Even upgrading a few critical motors with smart starters can give you:

- More insight

- Fewer surprises

- Greater peace of mind

The Future of Motor Starter Safety Is Proactive, Not Reactive

We’re moving beyond trip-and-reset culture. The next generation of motor starters doesn’t just shut things down—they keep things running smarter, longer, and safer.

- Safety isn’t just a switch anymore—it’s a data point, a dashboard, a decision tool.

Conclusion

In industrial settings, there’s no room for guesswork. Motors power your process, but motor starters protect it—and the people working around it. From preventing overloads and short circuits to avoiding dangerous restarts and mechanical stress, the right motor starter acts as a front-line defense against downtime and disaster.

We’ve walked through the types of starters available, the safety mechanisms built into each, and the evolving role of smart technologies in modern electrical systems. Whether you’re managing a small facility or overseeing large-scale integrations, it’s clear: motor starter safety is a foundational part of your system’s reliability.

If you’re unsure whether your current starters are doing enough—or if you’re planning upgrades and want to avoid costly mistakes—it’s worth having a conversation with someone who knows this inside and out.

At Electrical Power and Control, we’ve been helping professionals like you choose the right motor starters for over 25 years. If you need support selecting, sizing, or sourcing the safest solution for your operation, give us a call at 205-463-5260. We’ll help you find what fits, explain why it matters, and make sure you’re not leaving safety—or performance—to chance.