Table of Contents

Toggle- What Is an Air Circuit Breaker (ACB)?

- What’s The Purpose Of Air Breakers in Industrial Electrical Safety

- How ACBs Work: The Inner Mechanics of Protection

- What Makes Air Breakers Smart, Safe, and Reliable by Design

- Where Air Breakers Prove Their Worth: Real-World Industrial Applications

- Air Breakers vs Other Breaker Types: What Makes Them Different

- How to Select the Right Air Breaker for Your System

- Maintenance Tips for Long-Term Safety and Reliability

- Compliance and Safety Standards You Can’t Ignore

- Conclusion: ACBs Are a Safety Investment, Not an Expense

In industrial environments where power flows nonstop and precision is non-negotiable, safety isn’t just a requirement it’s a responsibility. Whether you’re managing a manufacturing plant, a hospital, or a processing facility, a single electrical failure can lead to equipment damage, production delays, or worse injuries and regulatory consequences.

That’s where circuit protection becomes more than a formality.

Among the many types of protective devices, Air Circuit Breakers (ACBs) play a pivotal role in safeguarding large-scale electrical systems. Designed to interrupt massive fault currents and prevent arc flash incidents, these breakers are the unsung heroes behind your uptime and operator safety.

But not all circuit breakers are created equal and not every facility manager or contractor knows when and why an air breaker is the right fit.

In this guide, we’ll walk you through:

- What air breakers are and how they work

- Why they’re critical for modern industrial safety

- How they compare to other breaker types

- How to select and maintain the right ACB for your needs

Our goal is to simplify this complex topic so you can make confident decisions, reduce risks, and focus on what matters most running safe, efficient operations.

What Is an Air Circuit Breaker (ACB)?

If you’re wondering, “Do I actually need an air breaker?” that’s a fair question. Let’s start simple.

An Air Circuit Breaker (ACB) is a type of electrical protection device that automatically interrupts current when it detects a fault like an overload, a short circuit, or an earth fault. What makes it unique is that it uses air (not oil or gas) to extinguish the arc created during interruption. That makes it safer, faster, and cleaner for industrial environments.

So where do these actually show up?

You’ll usually find ACBs in:

- Main switchboards for large buildings or facilities

- Motor control centers (MCCs) that run multiple motors

- Heavy-load machinery panels

- Backup systems in hospitals, factories, and data centers

They’re not for small circuits; these are the big guns, designed to handle high current loads, usually in the range of 800 amps to 6,300 amps. Think of them as the security system that steps in when something really goes wrong in your electrical network.

Why air?

Unlike oil circuit breakers (which carry a fire risk) or vacuum breakers (which are better for very high voltage but not always practical), ACBs strike a balance. They’re:

- Safe: No flammable medium involved

- Low-maintenance: Easier to inspect and clean

- Flexible: With adjustable trip settings and smart accessories

- Reliable: Ideal for critical systems where uptime is non-negotiable

And best of all you don’t need a PhD to understand or use them. With a little guidance (you’re in the right place), you can spec, source, or troubleshoot an ACB with confidence.

What’s The Purpose Of Air Breakers in Industrial Electrical Safety

Let’s not sugarcoat it electrical safety in industrial environments is high-stakes. One misstep in circuit protection and you’re looking at downtime, damaged equipment, OSHA violations, or worse someone getting hurt.

Air circuit breakers (ACBs) don’t just check a box on your compliance list; they’re a frontline safety measure built for environments where power loads are massive and the margin for error is razor thin.

Here’s what they protect you from:

- Overloads: When equipment draws more current than it should, ACBs step in before wires melt or motors burn out.

- Short Circuits: A sudden surge of current can destroy systems in milliseconds ACBs detect and disconnect fast enough to prevent cascading damage.

- Earth Faults: When current leaks to the ground, ACBs break the circuit and protect both people and infrastructure.

You might already have breakers in place. But here’s the real question: Are they built for your environment and load?

Because not all breakers can:

- Handle high currents without degrading over time

- Trip with precision and avoid nuisance interruptions

- Isolate only the faulty zone without shutting down your whole system

ACBs are engineered to do exactly that. Especially in industries where uptime matters just as much as safety like manufacturing, healthcare, data centers, and food processing.

Bonus: They help avoid fires.

Oil-based breakers carry flammability risks. ACBs? Not so much. By using air as the arc extinguishing medium, they eliminate one of the major safety concerns in older installations and they do it with fewer moving parts, meaning less wear and less maintenance.

So when you’re choosing protection for your people and equipment, you’re not just picking a part. You’re making a decision that impacts safety, compliance, performance, and your peace of mind.

How ACBs Work: The Inner Mechanics of Protection

Let’s say you’ve got a short circuit in your system, a serious one. One that could fry your equipment, shut down your line, or worse, put someone in harm’s way.

You need your circuit protection to do more than just exist. You need it to act instantly, interrupt the fault, and keep the rest of your system safe. That’s exactly what an air circuit breaker (ACB) is designed to do.

But how? What’s actually happening inside that metal box?

It’s easier to understand than you might think.

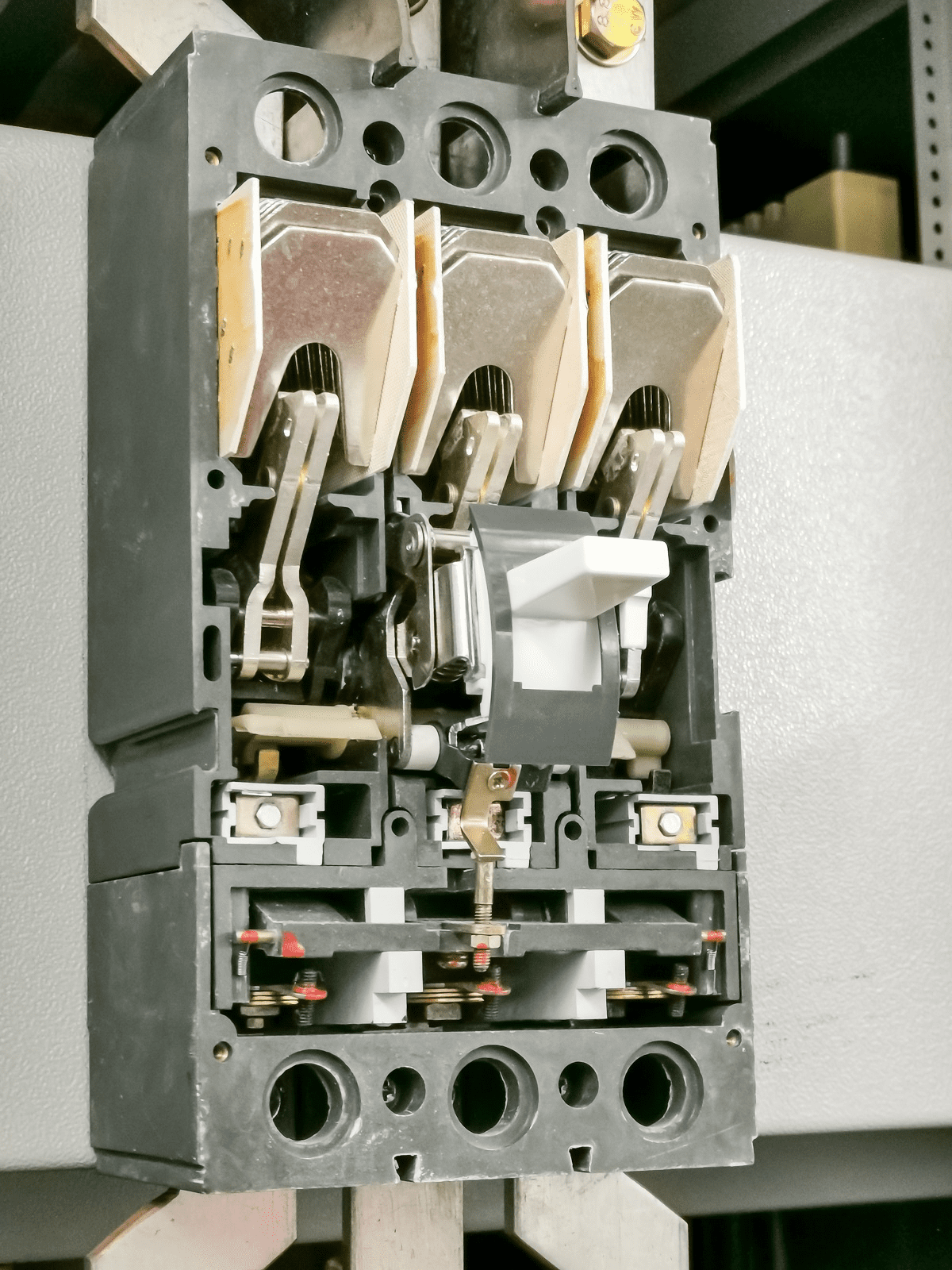

The moment a dangerous spike in current is detected whether it’s from an overload, a fault, or a grounded wire, the breaker trips. And inside the ACB, several components snap into action at once.

There’s a set of internal contacts that pull apart to open the circuit. This is where the danger peaks because that separation creates an electrical arc, like a mini lightning bolt, trying to jump across the gap.

Left unchecked, that arc could destroy components or even ignite a fire. But ACBs have built-in systems to stop it in its tracks.

Here’s where the air part comes in.

Instead of using oil or a sealed vacuum chamber, an ACB relies on the surrounding air paired with devices like arc chutes and blowout coils to stretch, cool, and extinguish the arc almost instantly. The arc chute acts like a maze that breaks the arc apart and cools it down. Meanwhile, the blowout coil generates a magnetic field that forces the arc away from the contacts and into the chute.

And just like that, the threat is neutralized.

There’s no fire risk from flammable oils. No waiting on vacuum-sealed units to be replaced. No wondering whether the trip happened cleanly. Everything happens out in the open, visible, maintainable, and fast.

This kind of design also makes the ACB far easier to inspect and service. You can check for wear, clean the contacts, or swap out arc chutes all without needing specialized tools or factory servicing. For someone who values uptime and predictability, that matters.

So while the inner workings of an ACB might seem complex on paper, the real takeaway is simple:

It’s built to protect, built to last, and built to be understood by the people who actually rely on it.

Not just the engineer who specs it. Not just the inspector checking the panel. But the facility manager, the contractor, the team lead the one responsible when things go wrong.

And with the right ACB in place? They go wrong a whole lot less.

What Makes Air Breakers Smart, Safe, and Reliable by Design

Choosing the right breaker isn’t just about specs, it’s about trusting the thing that stands between your system and disaster.

Air circuit breakers (ACBs) earn that trust by combining flexibility, visibility, and built-in intelligence all without overcomplicating your life.

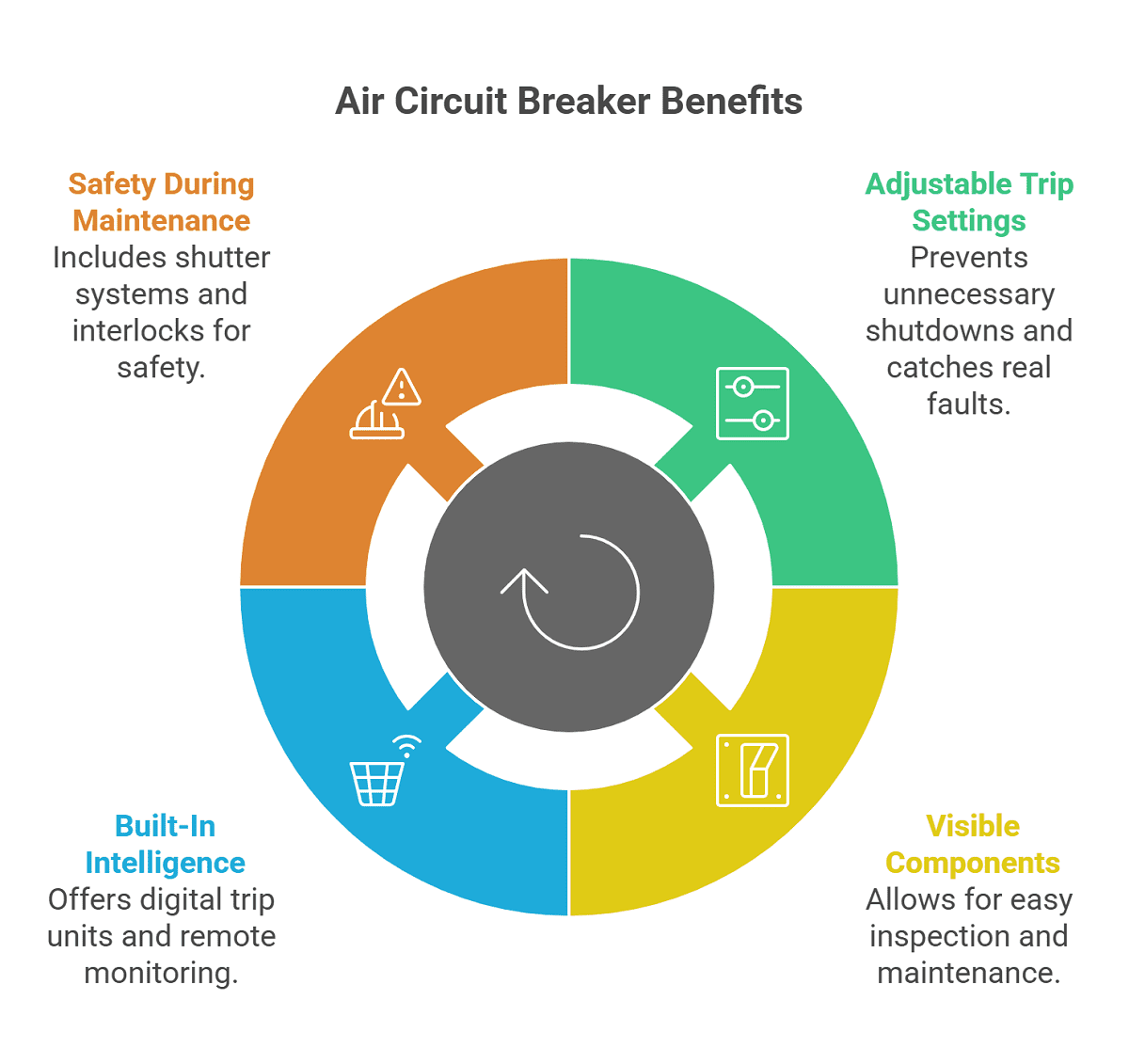

Adjustable Trip Settings: You’re in Control

One of the biggest frustrations in power systems? Breakers that trip when they shouldn’t or don’t trip when they need to. Both are a problem.

ACBs let you fine-tune trip thresholds so they match your actual system conditions. That means:

- You avoid unnecessary shutdowns that kill uptime

- You catch real faults before they escalate

- You tailor protection to match load type, not just load size

It’s one of the easiest ways to prevent equipment damage without over-engineering your panel.

Visible, Maintainable Components

Here’s something you don’t get with sealed breakers: peace of mind through inspection.

With an ACB, you can:

- Open the unit up

- Visually inspect arc chutes, contacts, and trip mechanisms

- Clean and replace parts without special tools or sending it off-site

You don’t have to guess whether a component is worn or hope your breaker still trips correctly. You can actually check.

Built-In Intelligence (When You Need It)

Not every system needs smart features but when you do, ACBs are ready.

Depending on the model, you can get:

- Digital trip units for better fault detection

- Remote monitoring so your team knows what’s happening in real-time

- Motorized reset for panels in hard-to-reach areas

- Programmable relays to feed data into your broader automation system

Smart doesn’t have to mean complicated especially when it makes failure less likely.

Designed for Safety During Maintenance

ACBs are built to prevent accidents before they happen.

Most models include:

- Shutter systems that cover live parts automatically

- Interlocks that stop you from switching on power during a panel service

- Mechanical indicators to show breaker status at a glance

That means safer conditions for your team and fewer compliance headaches for you.

Bottom Line: It’s Protection You Can Rely On

An ACB isn’t just a component. It’s a commitment to:

- Less guesswork

- Safer systems

- Fewer surprises

- And a better experience for the person who has to actually deal with the panel when things go wrong

When you install the right ACB, you’re not just protecting your equipment, you’re protecting your people and your performance.

Where Air Breakers Prove Their Worth: Real-World Industrial Applications

In the industrial world, no two facilities look the same. But one thing they all have in common? When the power fails, everything stops.

That’s where air circuit breakers quietly do their most important work not just by sitting in a panel, but by showing up when it counts.

In a busy manufacturing plant

Motors are running all day, machines are switching loads on and off, and the system is constantly shifting. Electrical noise, unexpected surges, or a single short circuit can bring the whole line to a halt. But with ACBs in place, the fault is detected fast, the problem is contained to the zone where it happened, and the rest of the operation keeps moving. That’s the kind of protection that doesn’t just prevent damage it protects delivery schedules, client relationships, and reputation.

Inside food and beverage facilities

The stakes look different. You’re dealing with wet zones, sanitation compliance, and equipment that’s often exposed to the elements. Fire risks are unacceptable, and flammable oil breakers just won’t cut it. ACBs, with their air-based arc interruption and outdoor durability, offer a level of safety that aligns with regulatory demands and gives operators the confidence to open up panels without fear.

In hospitals, data centers, and labs

Downtime isn’t just a nuisance, it’s a risk multiplier. One breaker trip can jeopardize patient safety or trigger a cascade of data loss. But ACBs step in with adjustable trip settings that protect without overreacting, and advanced units can integrate directly with smart building systems. That means faults can be logged, diagnosed, and reset often before the staff even realizes something’s happened.

Heavy industries like oil and gas, chemical processing, and large-scale infrastructure

They face some of the harshest electrical environments out there. Long cable runs. High fault currents. Remote access challenges. These aren’t places for fragile components. They demand breakers that can absorb punishment, extinguish serious arcs, and be restored without flying in a specialist. ACBs are built for that kind of reliability, with options for motorized operation, robust enclosure ratings, and built-in maintenance indicators.

Across all of these industries, the pattern is clear:

Where the loads are high, the risks are real, and the margin for failure is slim, air circuit breakers deliver protection that teams can trust.

They’re not the flashiest part of your system but when things go sideways, you’ll be glad they’re there.

Air Breakers vs Other Breaker Types: What Makes Them Different

It’s easy to assume that all circuit breakers do the same job and technically, they do. They interrupt dangerous currents. They protect your people and equipment. They keep your system safe.

But once you step into the real world of industrial systems, it becomes clear: not all breakers are built for the same battles.

Here’s where air circuit breakers (ACBs) differ and why that difference matters when the stakes are high.

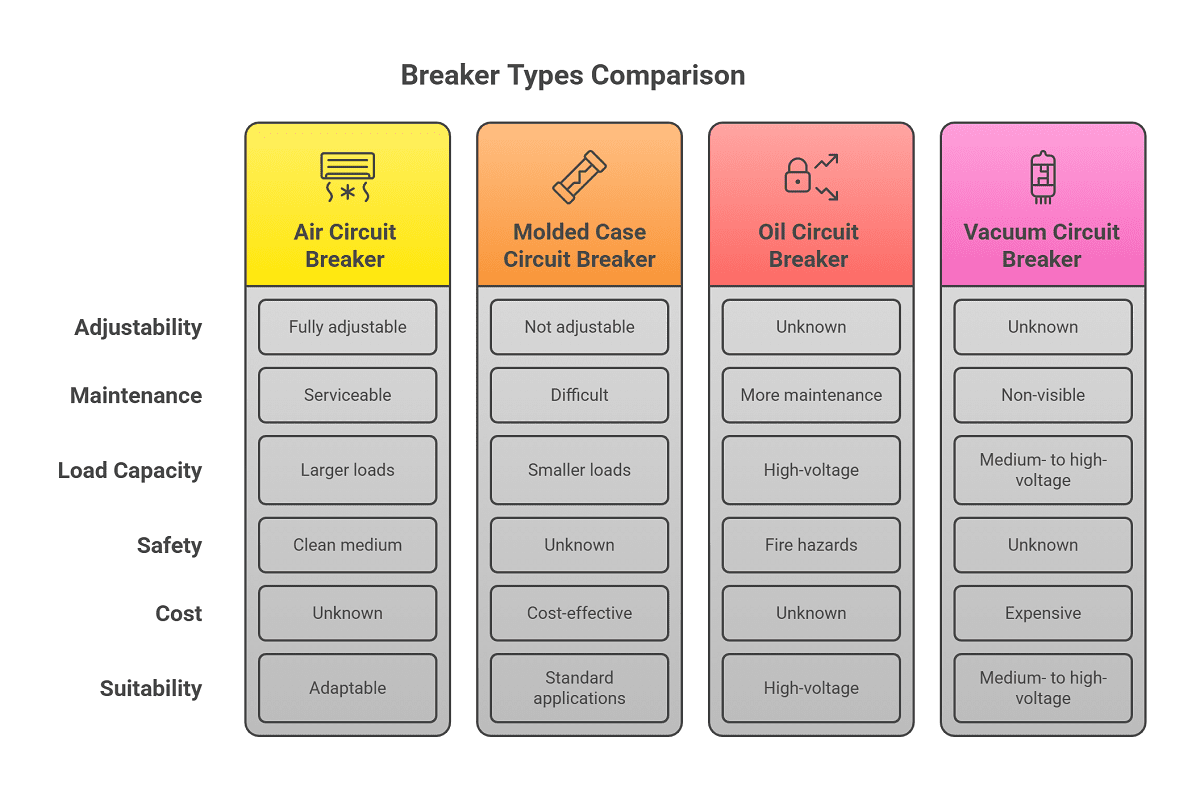

Molded Case Circuit Breakers (MCCBs)

MCCBs are great for smaller loads and standard applications. They’re compact, cost-effective, and easy to install. For office buildings, small commercial panels, or less complex systems, they’re often the go-to.

But here’s the catch:

- MCCBs are typically not adjustable, meaning you’re stuck with factory settings.

- They’re often sealed units, making maintenance or inspection difficult.

- They’re not designed for high-current, high-demand systems which makes them risky in environments with large motors or sudden surges.

In contrast, ACBs are fully adjustable, serviceable, and built to withstand much larger loads which is why they dominate in industrial power distribution.

Oil Circuit Breakers

These used to be the standard in high-voltage applications until we realized the safety risks.

- Oil breakers use flammable insulating fluid, which means fire hazards during a fault.

- They also require more maintenance and special handling for fluid inspection, leaks, and refills.

ACBs eliminate those concerns by using air as a clean, non-flammable, accessible medium. There’s nothing to leak, nothing to ignite, and nothing hazardous to clean up after a trip. That’s a huge win in safety-conscious environments.

Vacuum Circuit Breakers (VCBs)

VCBs are often used in medium- to high-voltage systems. They’re compact and reliable, with long service life and minimal arcing. But they’re also:

- Expensive to replace or repair

- Sealed and non-visible, meaning internal wear isn’t always obvious

- Less suited for lower-voltage industrial environments where flexibility and manual servicing matter

ACBs, on the other hand, are easier to inspect, simpler to maintain, and more adaptable especially when you’re managing a facility that needs hands-on control and rapid access.

The Real Comparison

Air breakers might not always be the smallest or cheapest option but when you need adjustability, serviceability, and serious load capacity, they’re the right tool for the job.

They’re ideal for:

- Mission-critical environments

- Custom electrical builds

- High-fault current protection

- Facilities that can’t afford sealed, untouchable, “just hope it works” breakers

When the system is simple, other breakers work just fine. But when it gets real ACBs are the ones you want watching your back.

How to Select the Right Air Breaker for Your System

By this point, you probably know one thing for sure: not all breakers are created equal. But even once you’ve narrowed it down to air circuit breakers, the next question is, which one?

If you’re sourcing a new breaker or replacing an old one, you need more than just a catalog number; you need clarity. And you need to get it right the first time.

Here’s how to do that without second-guessing.

Start with the Load

Everything starts here.

How much current is your system pulling under normal conditions? And what does that spike to under full load?

Look at:

- Rated current (In) the max continuous current your breaker will handle

- Breaking capacity (Icu or Ics) the max fault current it can safely interrupt

In other words: Can this breaker handle the worst-case scenario? If not, keep looking.

Match the Voltage

Seems obvious, but it’s often overlooked.

Make sure the ACB is rated for:

- The system voltage (e.g., 380V, 415V, 690V)

- The frequency (typically 50Hz or 60Hz)

- The voltage tolerance if your loads are particularly sensitive

Get this wrong and even the best breaker will fail you.

Know Your Application

What’s this breaker actually protecting?

A single motor load behaves differently than a transformer, and a backup generator behaves differently than a switchgear panel. Make sure the ACB’s trip curve and protection settings align with the type of equipment it’s guarding.

This is where working with experts, not just ordering online makes all the difference.

Consider Installation & Mounting

Think about physical space, access, and future servicing.

Do you need:

- A fixed-type breaker? (Less flexible but more compact)

- A draw-out unit? (Easier maintenance, safer isolation)

- Front or rear connections? (Depends on your panel layout)

The right choice saves hours of retrofitting headaches.

Look at Compliance & Standards

You want a breaker that’s not just capable but certified.

Check for:

- IEC 60947-2 compliance (international safety standard)

- UL or CSA certification if you’re in North America

- NEMA ratings or IP codes for environmental protection

Choosing certified equipment protects your facility and your liability.

Bonus: Think Beyond the Breaker

Sometimes what matters most isn’t the breaker, it’s what comes with it.

Do you need:

- Remote monitoring?

- Shunt or undervoltage trips?

- Communication protocols (Modbus, Ethernet)?

- A supplier who actually answers the phone when something breaks?

This is where Electrical Power & Control makes the difference not just in what we stock, but in how we support you through selection, setup, and service.

Choosing the right ACB isn’t about overthinking.

It’s about knowing what matters and making a call you won’t regret later.

Maintenance Tips for Long-Term Safety and Reliability

Installing an air circuit breaker is a smart move but keeping it safe, reliable, and compliant over time? That’s where the real work begins.

Like any piece of equipment, ACBs need attention. Not every day. Not even every week. But they do need regular care because if they fail when you need them most, you don’t get a do-over.

Here’s how to make sure that doesn’t happen.

1. Make Inspection a Routine Not a Reaction

It’s easy to forget about the breaker until something goes wrong. But by that point, the damage is already done.

Instead:

- Schedule monthly visual checks for wear, dust buildup, or signs of heat stress

- Look for loose terminals, discoloration, or mechanical fatigue

- Keep the inspection documented for compliance and trend tracking

Simple checks now can prevent complex problems later.

2. Clean Internals Carefully and Consistently

Dust, debris, and moisture aren’t just ugly they’re dangerous.

They can cause tracking, insulation breakdown, and eventual failure.

Plan for:

- Quarterly cleanings (more often in dirty or high-moisture environments)

- Safe use of non-conductive cleaning tools

- Checking the condition of arc chutes, contact surfaces, and terminals

Always power down and isolate before cleaning and if your team isn’t trained, call in support. Your life literally depends on it.

3. Test the Trip Mechanism Don’t Just Assume It Works

The breaker’s job is to trip when it’s supposed to. But mechanisms wear out, springs fatigue, and electronic trip units can silently fail.

That’s why it’s critical to:

- Functionally test the trip mechanism at least once a year

- Use proper test kits or injectors for digital models

- Record results and compare them year-over-year

If you can’t test in-house, partner with a qualified service provider (hey, we know a few).

4. Replace Worn Parts Before They Fail

Most ACBs are modular meaning you can replace contacts, arc chutes, handles, and more without buying a whole new unit.

Don’t wait for a catastrophic trip.

If you see wear, hear unusual clicking, or get inconsistent trip behavior, replace the part. It’s cheaper than replacing the entire panel or paying for downtime.

5. Use Predictive Tools to Get Ahead of Failures

Want to go from reactive to proactive? Start integrating predictive maintenance tools.

Options include:

- Thermal imaging to detect overheating before it causes damage

- Remote monitoring for real-time trip alerts and system health

- Breaker condition sensors that notify you when something’s off

These aren’t just bells and whistles, they’re the new baseline for modern facilities that care about uptime and safety.

Trust is Built in the Quiet Moments

Your breaker isn’t flashy. It doesn’t get noticed when things are running well. But if it’s not maintained, it becomes the weakest link in your entire electrical system.

Make maintenance part of your rhythm and if you need help building a program that works, Electrical Power & Control is here for that too.

Compliance and Safety Standards You Can’t Ignore

Let’s be honest: nobody enjoys digging through safety codes. But if you’re in charge of electrical systems, whether you’re building them or maintaining them, compliance isn’t optional.

It’s your responsibility, and your risk.

The good news? Air circuit breakers are built to meet the kinds of standards that regulators (and insurers) actually care about. But only if you know what to look for.

Here’s what matters and what you can’t afford to skip.

IEC 60947-2: The Global Benchmark for Breaker Safety

This international standard defines the performance, testing, and safety requirements for low-voltage circuit breakers.

If your breaker isn’t compliant with IEC 60947-2, you’re already on shaky ground.

This standard covers:

- Breaking capacity

- Mechanical endurance

- Short-circuit behavior

- Coordination with other protection devices

Look for this stamp when sourcing. It’s the industry’s way of saying, “this breaker won’t let you down when it matters.”

🇺🇸 UL 489 & CSA C22.2: North American Standards That Keep You Covered

If you’re operating in the U.S. or Canada, these certifications are key.

UL 489 and CSA C22.2 ensure that the breaker:

- Performs safely in North American systems

- Meets local electrical code (NEC, CEC)

- Is legally acceptable for installation in commercial and industrial settings

Breakers without these ratings might work but they won’t pass inspection. And if something goes wrong? You’re holding the liability.

NEMA & IP Ratings: Know Your Environment

It’s not just how your breaker works, it’s where it works.

- NEMA ratings (U.S.) and IP codes (international) tell you how well the breaker enclosure resists dust, moisture, and environmental hazards.

- For outdoor installs, food processing zones, or dusty plant floors, a standard panel just won’t cut it.

Get the right rating upfront, and you won’t have to rip and replace later.

OSHA & NFPA 70 (NEC): Beyond the Panel

If you’re responsible for worker safety or facility compliance, the National Electrical Code (NEC) and OSHA regulations apply to more than just the breaker they apply to:

- How it’s installed

- How it’s labeled

- How it’s maintained and accessed

Air circuit breakers support these standards by offering features like lockable interlocks, visible trip status, and safe manual operation all of which matter when inspectors walk in or when your team needs to service a live system.

Pro Tip: Document Everything

Compliance isn’t just about having the right equipment; it’s about being able to prove you do.

That means:

- Keeping inspection logs

- Recording trip test data

- Saving installation specs and certifications

If something ever goes wrong, that paper trail becomes your shield.

Compliance Isn’t a Burden, It’s a Backstop

You don’t follow standards just because the law says so.

You follow them because you’re responsible for keeping people safe, for protecting expensive systems, and for making sure your operation doesn’t come grinding to a halt after an inspection.

And that’s exactly why choosing the right breaker and the right partner to source it from makes all the difference.

Conclusion: ACBs Are a Safety Investment, Not an Expense

If you’ve read this far, you’re probably not someone who takes shortcuts with safety.

You understand that when electrical systems fail, the cost isn’t just measured in repair bills; it’s measured in downtime, missed deadlines, lost trust, and sometimes, real physical danger.

That’s what makes air circuit breakers such a smart choice.

They’re not just another line item in your panel build. They’re:

- A buffer between your system and catastrophic failure

- A safeguard for your team, your equipment, and your uptime

- A tool that gives you control in environments where control is everything

They offer clarity, flexibility, visibility, and long-term reliability exactly what industrial professionals need when things get unpredictable.

And while the initial price tag might be higher than other breaker types, it’s nothing compared to the cost of system-wide shutdowns, failed inspections, or preventable accidents.

So What Now?

If you’re in the middle of a project or facing an urgent replacement now’s the time to get it right.

You don’t need to figure it out alone.

Electrical Power & Control has spent over 25 years helping contractors, engineers, and facility managers:

- Match the right breaker to the right environment

- Source components, fast even hard-to-find ones

- Customize enclosures, panels, and accessories

- Get emergency support when timelines get tight

Whether you know exactly what you need or just know what problem you’re trying to solve, we’re here to help you figure out the rest.

Because in this industry, the people who succeed are the ones who have the right tools and the right partners backing them up.

Reach out now, and we’ll help you figure out what you actually need, not just what a spec sheet says. Whether it’s a standard ACB, a custom panel, or a fast replacement, you’ll get straight answers and fast support from people who know this world inside out.

Contact us today →

Because struggling through it solo isn’t the only option.