Table of Contents

ToggleAbove is just one of the videos in our investment recovery series focusing on the value of your demolition parts, broken-down machinery, and unneeded inventory. The overall theme of the articles and videos in this series is the concept of inventory efficiency…

In other words, how do you get the most money back from the money you put into buying your inventory? That’s essentially what investment recovery and inventory efficiency are all about.

What Do You Do With Electrical Parts You Don’t Need?

When It’s Demolition Time

If you’re demolishing a building and find scrap parts around, we want to buy them. Sure, you could send them to the scrapyard where they’ll be repurposed, but you’ll only get pennies in return. With us, you can sell your scrapped electrical parts to regain some of your money back.

When It’s Upgrade Time

Before discarding broken machinery, consider contacting us for an assessment. Oftentimes, machinery can be repurposed within your facility, saving money on replacement costs. If it’s no longer usable, we’ll evaluate its condition and offer you a fair price. This gives you a return on your investment while clearing space for new, more efficient equipment.

When It’s Spring Cleaning Time

If you find that you don’t have enough space for the parts you actually use, consider selling us the old, outdated ones. Clutter is never a good thing, especially if that clutter is made up of unneeded parts.

We can help breathe life into your dead inventory by buying your old parts and getting you back a portion of the money you originally paid for them. If you need to purchase new replacement parts, we can help with that, too.

Why Sell To Us?

By selling to us, you help prevent valuable parts and machinery from ending up in landfills, reducing environmental waste. The sheer amount of trash that landfills accumulate daily is staggering.

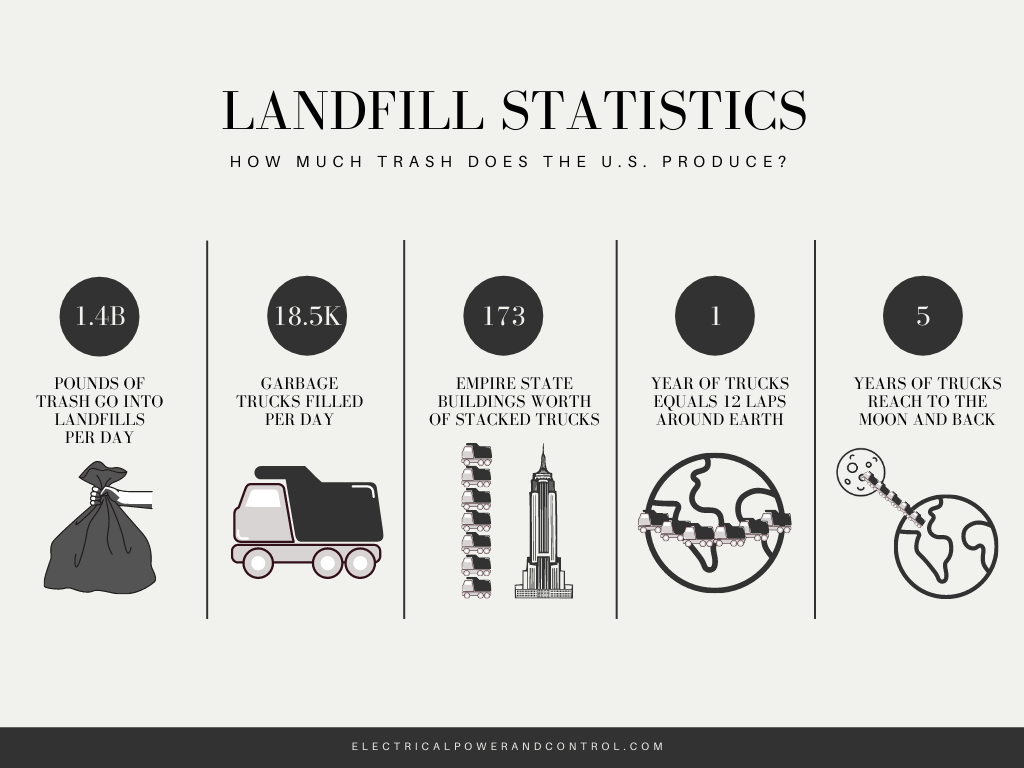

Did you know that 1.4 billion pounds of trash go into landfills in the United States per day? On top of that, it takes 18,500 trucks per day to move it all. If those trucks were stacked, they would equal the height of 173 Empire State Buildings. If one year’s worth of those trucks were laid out end to end, they would stretch 12 laps around the Earth at the equator. Lastly, five year’s worth of those trucks laid out end to end would stretch the distance to the moon and back.

To help you visualize…

Another huge benefit of selling to us is that you’ll recuperate some of the money that you put into your inventory in the first place. Why throw away a part or piece of equipment when you could get a return on your investment instead?

Tips for Inventory Efficiency

Efficient inventory management reduces costs, improves productivity, and makes everything run more smoothly. Here are some things you can do to improve your inventory efficiency…

Know Your Equipment Inside and Out

Understanding the equipment and parts you manage is the foundation of inventory efficiency. To know your equipment inside and out…

- Keep Detailed Inventory Records: Keep records that include equipment specifications, parts used, replacement schedules, and suppliers.

- Practice Predictive Maintenance: Use data analytics or maintenance logs to predict when parts will need replacement, which helps minimize downtime.

- Have Compatibility Awareness: Know which parts are interchangeable or universally compatible to avoid overstocking redundant items.

- Build Vendor Relationships: Build strong relationships with suppliers who can provide parts quickly or offer expert advice on equipment-specific needs.

Avoid Excess Clutter

Excess inventory can drain resources and make your workspace less functional, so getting rid of clutter helps you with efficient inventory practices. Try these tips to help reduce clutter:

- Stock Turnover Strategy: Regularly review stock levels and remove slow-moving items to focus on high-demand inventory.

- Visual Management: Use clear bins, racks, or shelves with labeled sections for quick identification and access.

- Regular Cleanup Routines: Schedule reviews of inventory now and then to remove or reorganize outdated or unnecessary items.

Practice Preventative Maintenance

Preventative maintenance extends the life of your equipment and makes sure that important parts are always available, leading to a more efficient inventory. Try these strategies:

- Scheduled Inspections: Create a calendar for regular part and equipment checks.

- Maintenance Kits: Prepare kits with commonly used tools and parts for quick repairs.

- Critical Spares Strategy: Identify the most critical parts for your operations and ensure they are always in stock.

Engage Your Team

Your team is important for maintaining an efficient inventory system. There are several things you can do to make sure everyone is on the same page…

- Training and Education: Provide employees with clear training on how to handle, store, and record inventory accurately.

- Ownership Culture: Encourage employees to take ownership of specific areas of inventory to enhance accountability.

- Feedback Loops: Create a system where employees can suggest improvements or report inefficiencies in inventory management.

Optimize Storage and Space Usage

Efficient storage systems make it easier to locate and access inventory. Here are some ways to make better use of your storage space:

- Vertical Storage Solutions: Use shelving and racks to maximize vertical space in your warehouse.

- Zoning Systems: Divide your warehouse into zones based on item type, size, or usage frequency for easier navigation.

- Climate Control: Ensure sensitive parts and equipment are stored in temperature and humidity-controlled environments to prevent damage.

Regular Inventory Audits

Regular audits help you identify inefficiencies and keep inventory records accurate. You shouldn’t neglect this part of inventory management, however you decide to do it! Here are some ideas to get you started:

- Cycle Counting: Perform routine counts of small sections of inventory instead of annual audits to save time and maintain accuracy.

- Data Reconciliation: Compare physical inventory counts with digital records to identify inconsistencies.

- Audit Checklists: Use checklists to ensure all parts and equipment are accounted for during audits.

Prioritize High-Value Items

Another way to create a more efficient inventory system is to focus your attention on the inventory that has the greatest impact on your day-to-day operations…

- ABC Analysis: Categorize inventory into A (high-value), B (medium-value), and C (low-value) groups, dedicating more resources to managing A items.

- Secure Storage: Place high-value items in secure, easily accessible locations to prevent theft or damage.

Develop Clear Inventory Policies

Clear guidelines for handling and managing inventory create consistency across your organization.

- Standard Operating Procedures (SOPs): Document and distribute SOPs for receiving, storing, and issuing parts.

- Access Controls: Limit access to inventory areas to authorized personnel only.

- Return and Exchange Policies: Implement policies for returning or exchanging defective or excess items to suppliers.

By following these tips and implementing efficient practices, you’ll reduce costs, save time, and enhance the productivity of your inventory management system. These improvements not only benefit your day-to-day business operations but also contribute to long-term sustainability and growth.

Additional Disposal Practices

Responsible disposal of parts and equipment is necessary for a sustainable future. Other than taking advantage of our investment recovery services, here are some other ways that you can dispose of your unneeded parts and equipment:

- Refurbishing Parts: Extend the life of old equipment through repairs and upgrades.

- Secondhand Market: Sell functional parts and equipment to businesses in need, reducing waste and recouping costs.

- Specialized Facilities: Partner with facilities that recycle electronic and electrical components to recover valuable materials like copper, aluminum, and rare earth metals.

- Educational Institutions: Donate outdated but functional equipment to schools or training centers for educational purposes.

- Nonprofits: Partner with organizations that can repurpose your equipment for charitable initiatives.

Partnering With Electrical Power and Control

At Electrical Power and Control, we’re committed to helping you get a return on your investment while contributing to a more sustainable world. Whether you’re clearing out clutter, upgrading your equipment, or demolishing a building, we’re here to help turn your unused parts into cash.

For help in improving your inventory efficiency, call us at (205) 812-5402 or visit our Sell To Us page today. Together, we can create a cleaner, more organized future!