Table of Contents

ToggleAir circuit breakers are designed to handle large amounts of power and high currents, making them an ideal choice for those who need reliable power and protection. In this blog post, we will explore things you should know about air circuit breakers: what an air circuit breaker is, the parts, components, and types of air circuit breakers, the benefits of using them, troubleshooting common issues, and how to select the right one for your application.

By the end of this post, you should have a good understanding of why air circuit breakers may be the right choice for your electrical system.

What is an Air Circuit Breaker?

An air circuit breaker is a type of circuit breaker that uses air to extinguish the arc that forms when contacts open. The contacts are housed inside arc chutes, which help contain and quench any arc that may occur during the opening and closing of the breaker.

The main benefit of using an air breaker is its speed; it can trip much faster than conventional mechanical or thermal-magnetic types of breaker systems.

Air circuit breakers are highly effective at clearing high short-circuit currents, as well as safeguarding electrical circuits from damage caused by overcurrent or short circuits. They toggle an arc of electricity through the air when current overloads occur and can be reset manually or automatically after tripping.

How Are ACBs Different From Regular Circuit Breakers?

If you are looking for an efficient way to protect your electrical systems and components, air circuit breakers (ACBs) may be the right choice for you! ACBs offer several advantages over regular circuit breakers, and it is important to understand these differences before making a selection.

According to Quisure, ACBs are larger than MCCBs (molded case circuit breakers) and have more volume. ACBs can also handle higher currents and have a greater breaking capacity than MCCBs.

Both air circuit breakers and regular circuit breakers are electromechanical devices that react to high current levels by opening the circuit. The difference is in the type of medium used for arc quenching. ACBs use air, while other types of circuit breakers may use oil, vacuum, or SF6 gas.

ACBs also require less maintenance than regular circuit breakers since they operate in an environment exposed only to dust particles rather than dirt or other contaminants, and tend to be less expensive than regular ones.

Air Circuit Breaker Parts, Components, and Types

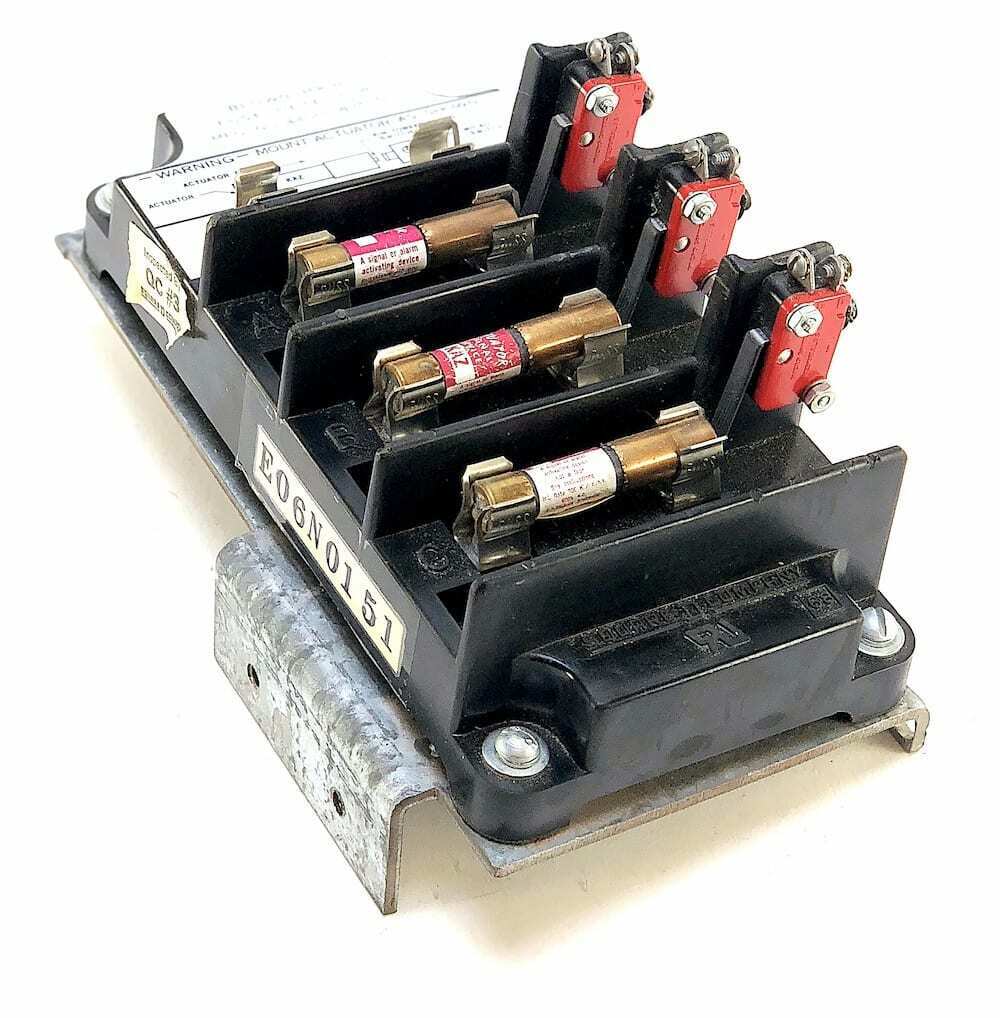

Air circuit breakers contain three basic parts: the contact, the arc extinguishing chamber, and the operating mechanism. They have built-in sensors that respond to an overload or fault current. The contact is connected to the arc extinguishing chamber, which rapidly quenches the arc when a fault or overload occurs. After this, an operating mechanism opens the contacts and trips the breaker.

Air circuit breakers are available in different voltage ratings, and many have adjustable trip settings for selecting the correct trip setting for a given application. It is important to understand its components before selecting an ACB as they will determine its functionality, such as voltage rating, electrical load capacity, ambient temperature, etc.

There are four types of air circuit breakers:

Plain Break Type ACB

This is the simplest type of air breaker. The contacts are shaped like horns, and the arc reaches from each point. Then, the breaker uses air pressure to extinguish the arc. Plain break-type ACBs can work with both current types and are generally used in low-voltage conditions.

Magnetic Blowout Type ACB

These have a voltage capacity of up to 11kV. This type uses a magnetic field that assists in eliminating the arc by using it to move the arc along the chutes, then pressurized air is utilized to get rid of it.

Air Chute ACB

Used in high voltage situations of 420kV or more, these ACBs have primary copper contacts and silver arcing contacts. When a break happens, the primary contacts are protected from the arc by separating before the arcing contacts.

Air Blast Circuit Breaker

Air blast circuit breakers extinguish the arcs by opening a valve, letting pressurized air move through the arc chute where it then moves the arc up, lengthens it, and extinguishes it. These breakers can work with voltages up to 15kV.

Best Practices for Maintenance of Air Circuit Breakers

Proper maintenance is essential for ensuring your air circuit breaker (ACB) continues to perform optimally. Here are some key maintenance tasks:

- Regular Inspections: Conduct visual inspections for signs of wear, corrosion, or damage. Check for loose connections, leaks, or excessive dirt buildup.

- Cleaning: Regularly clean the breaker to remove dust, dirt, and other contaminants. Use a soft brush or compressed air to avoid damaging components.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations. This helps ensure smooth operation and prevents premature wear.

- Contact Inspection: Inspect the contacts for pitting, burning, or excessive erosion. If necessary, clean or replace them.

- Air System Checks: If your ACB uses compressed air, regularly inspect the air supply system for leaks, moisture, or contamination.

- Functional Testing: Periodically test the breaker’s operation to ensure it trips at the correct current levels and resets properly.

- Calibration: If your ACB has adjustable trip settings, ensure they are calibrated correctly.

- Record Keeping: Maintain a maintenance log to track inspections, repairs, and any issues that arise.

One consideration regarding working with air circuit breakers is arc flash calculations and requirements designed for safety reasons, such as preventing arc flash incidents caused by improper installation or maintenance activities on energized equipment.

On installation, make sure you understand how arc flash calculations impact your system design so that all components meet safety standards and local codes regarding human safety during operation.

To ensure safe operation at all times, it is best practice to install AFCI (Arc Fault Circuit Interrupter), which provides additional protection against certain types of faults caused by arcing between conductors or between conductor/ground. This device can be installed along with regular ACBs to give an extra layer of protection, reducing risks associated with unprotected circuits.

Benefits of Using an Air Circuit Breaker

Air circuit breakers have a built-in resetting mechanism that allows them to quickly recover from electrical trips or surges without causing downtime for industrial operations by quickly re-energizing production equipment. They improve safety by quickly reducing the risk of electrical fires or overloads while eliminating maintenance costs associated with replacing fuses.

Also, air circuit breakers provide adjustable trip settings to meet specific application requirements while efficiently breaking current at higher voltages without generating sparks or noise. This also helps isolate damaged components from other parts of the system so that they can be protected from further damage if needed.

On top of all this, many ACBs come equipped with a warning alarm function that alerts operators before potential outages occur, so that action can be taken accordingly ahead of time.

For these reasons alone, it’s clear why air circuit breakers have become such an important part of industrial environments today. Their reliability ensures that operations run smoothly, while their ability to adjust their settings makes them highly configurable should needs change down the road.

Troubleshooting Common Air Circuit Breaker Issues

Encountering issues with your air circuit breaker can be frustrating and disruptive to operations. Here are some common problems and potential solutions:

- Frequent Tripping: This could indicate an overload, short circuit, or a problem with the breaker itself. Check for equipment malfunctions, wiring issues, or signs of breaker damage. If the problem persists, consult a qualified electrician.

- Delayed Operation: Slow tripping can compromise equipment protection. Inspect for mechanical obstructions, worn components, or issues with the air supply. Regular maintenance and calibration can help prevent this problem.

- Failure to Reset: A breaker that won’t reset might have a tripped internal mechanism or a faulty reset button. Check for any visible damage and try resetting again. If the issue persists, professional intervention is necessary.

Remember, attempting repairs without proper training can be dangerous. Always prioritize safety and seek expert assistance when needed.

Selecting the Right Air Circuit Breaker for Your Application

Choosing the correct air circuit breaker is crucial for optimal system performance and protection. Consider the following factors when making your selection:

- Voltage and Current Ratings: Ensure the breaker’s capacity matches your electrical system’s requirements.

- Interrupting Capacity: Select a breaker with an interrupting capacity that exceeds the potential fault current in your system.

- Environmental Conditions: Consider factors like temperature, humidity, and exposure to corrosive elements when choosing a breaker.

- Mounting Options: Ensure the breaker is compatible with your electrical panel and installation requirements.

- Future Expansion: Plan for potential growth by selecting a breaker with adequate capacity for future needs.

Industries such as manufacturing, data centers, and power generation have specific requirements. Consulting with an electrical engineer can help you choose the most suitable air circuit breaker for your application.

By carefully evaluating these factors, you can select an ACB that provides optimal protection and performance for your specific application.

In Short

Air circuit breakers offer a lot of advantages over traditional circuit breakers and are often a great choice for industrial and commercial applications. They provide superior protection against potential overloads or short circuits, require minimal maintenance, and can handle substantial power effortlessly.

Understanding the components of an air circuit breaker, along with its benefits and proper maintenance requirements, will help guarantee reliable operation and optimal safety in your electrical system.

Now that you understand the basics of air circuit breakers, it’s time to dive deeper. Read our article about the different types of industrial circuit breakers available and if you are interested in learning more about air circuit breakers and how Electrical Power and Control can help you, call us at 205-812-5402.