Table of Contents

Toggle- 4 Essential Steps for Electrical Safety: A Guide by Electrical Power & Control Consultants Inc.

- Learning from Electrical Safety Incidents: Key Questions and Insights

- Why Electrical Safety Matters in Industrial Settings

- Enhance Electrical Safety Awareness with Electrical Power & Control Consultants Inc.

4 Essential Steps for Electrical Safety: A Guide by Electrical Power & Control Consultants Inc.

Electrical safety isn’t just a checklist; it’s a commitment that protects lives, keeps projects on schedule, and ensures code compliance across every job site. Whether you’re installing control panels, maintaining switchgear, or troubleshooting machinery, following core safety steps is essential.

In this guide, we break down four simple yet critical actions you can take to reduce risk on any commercial or industrial site. These practices align with OSHA and NFPA standards, helping contractors, integrators, and plant managers build a safety-first culture from the ground up.

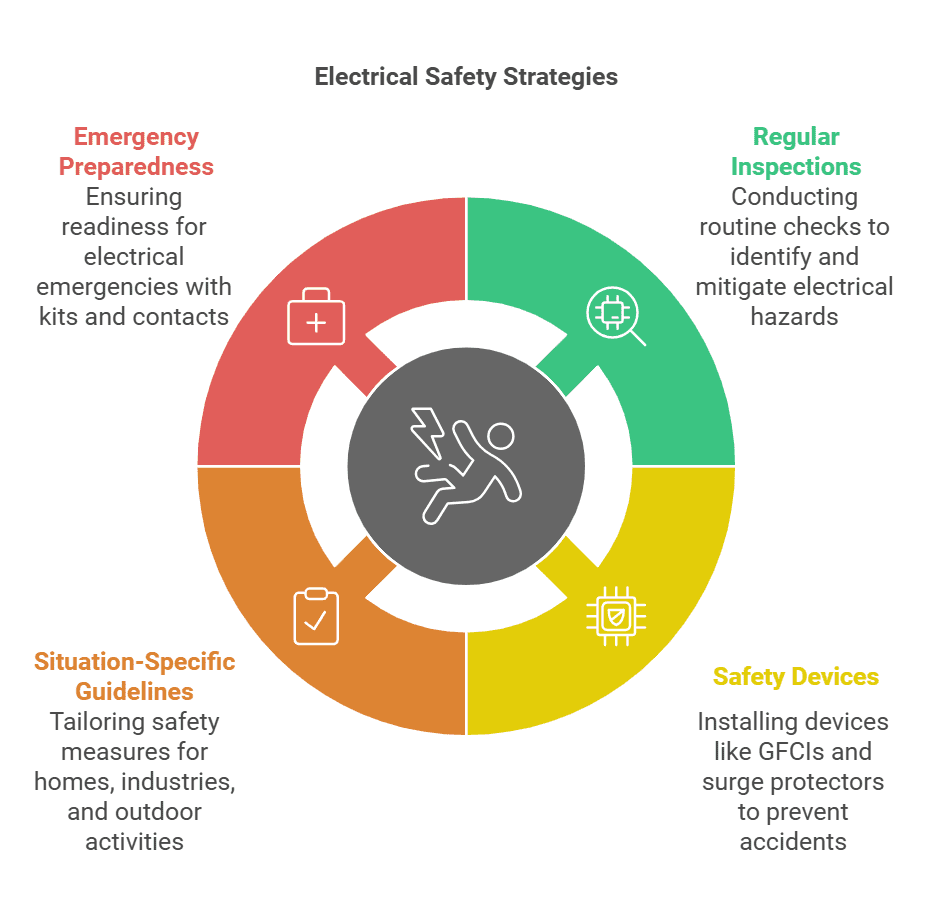

Electricity is an essential part of modern life, powering homes, industries, and businesses. However, without proper precautions, it can pose serious risks. At Electrical Power & Control Consultants Inc., we prioritize safety above all, ensuring our clients have the knowledge and tools needed to mitigate electrical hazards. Whether you’re an engineer, maintenance worker, or homeowner, these 4 essential steps for electrical safety will help you stay safe and protect your property.

Electrical Power and Control Consultants has over 25 years of experience in making sure your electrical needs are met efficiently and safely. Here is a quick list of ways to prevent electrical problems and damage, so you can keep going about your day securely.

Our CEO, Pat Sims, spoke with us about a problem with the power at a local superstore. Fortunately, he and the team at Electrical Power and Control were able to fix it quickly and efficiently.

In four simple questions, see how a reigning expert explains what happened, how it can be avoided, and what to do for your own business to prevent potentially costly electrical problems.

1. Conduct Regular Electrical Safety Inspections

Regular inspections are the cornerstone of electrical hazard prevention. By identifying potential issues early, you can prevent accidents and costly repairs.

- What to Check: Wiring, circuit breakers, electrical panels, and grounding systems.

- Why It Matters: Damaged or outdated systems increase the risk of electrical fires and shocks.

- Recommended Tools: Use electrical safety equipment like insulated gloves and voltage testers during inspections.

Pro Tip: Schedule an electrical safety audit annually to ensure compliance with safety standards and regulations.

Additional Things to Look For During an Inspection

- Discoloration on outlets or switch plates (may signal overheating)

- Buzzing or humming from panels, transformers, or breakers

- Extension cables used as permanent wiring

- Water intrusion near electrical systems (especially for industrial facilities)

- Overloaded or daisy-chained power strips

- Frequent tripping of the same breaker

Why Routine Inspections Improve Long-Term Safety

Regular inspections don’t just catch faults — they prevent costly failures. Small issues like loose connections or worn insulation can escalate into equipment damage, outages, or fire hazards if ignored.

Professional Insight You Can Add

For facilities with aging equipment, scheduling annual infrared (thermal) scans helps detect invisible hotspots before they fail.

2. Use Proper Electrical Safety Devices

Investing in the right safety devices can significantly reduce the risk of accidents in homes, offices, and industrial settings.

- Key Devices to Install:

- Ground Fault Circuit Interrupters (GFCIs) to prevent shocks in wet areas like kitchens and bathrooms.

- Surge protectors to shield appliances from power surges.

- Circuit breakers for efficient overload protection.

- Where to Focus: Areas with high electrical loads, such as industrial sites or workshops.

Bonus Tip: Don’t overlook extension cord safety—use cords with appropriate ratings for the devices they power.

Additional Devices Worth Considering

- Arc-Fault Circuit Interrupters (AFCIs) to prevent electrical fires

- Lockout/tagout (LOTO) kits for maintenance teams

- Industrial surge suppressors for sensitive machinery

- Voltage indicators on panels for safer troubleshooting

- Smart breakers that provide usage and load data

How Safety Devices Reduce Downtime

Safety gear doesn’t just protect people — it protects productivity. A $20 device can prevent thousands in downtime, repairs, and emergency response.

3. Follow Electrical Safety Guidelines for Specific Situations

Each environment has unique risks. Tailoring your approach to specific situations enhances safety and efficiency.

- For Homeowners:

- Ensure proper grounding of home appliances like refrigerators and washing machines.

- Use child proof outlets to protect kids.

- For Industrial Workers:

- Wear protective gear, including electrical safety boots and flame-resistant clothing.

- Conduct routine maintenance with a detailed electrical safety checklist.

- For Outdoor Activities:

- Avoid using electrical devices near water unless specifically designed for such use.

- Keep power tools away from rain or moisture.

Tip for Seniors: Install visual safety signs and opt for devices with larger, easy-to-read controls to improve accessibility.

Additional Situational Guidelines

During remodeling or construction:

- Confirm circuits are de-energized before cutting walls or ceilings

- Use temporary GFCI-protected power sources

In commercial environments:

- Replace worn extension cords immediately

- Keep electrical rooms clear of storage materials

- Train staff on basic electrical emergency responses

In industrial settings:

- Follow NFPA 70E compliance for energized work

- Maintain accurate single-line diagrams of the facility

- Use proper PPE like voltage-rated gloves, shields, and insulated tools

Real-World Tip

Miscommunication is a common risk. Always verbally confirm “all clear” before work begins — especially in multi-team environments.

4. Stay Prepared for Electrical Emergencies

Even with preventive measures, emergencies can still occur. Being prepared ensures quick and effective responses.

- Emergency Must-Haves:

- A well-stocked first-aid kit with burn treatment supplies.

- Emergency contact numbers for electricians and local fire departments.

- What to Do During a Power Outage:

- Use portable generators safely—never operate them indoors or near windows.

- Turn off sensitive electronics to avoid damage from power surges.

Fire Prevention Tip: Install smoke detectors near electrical panels and outlets to detect potential issues early.

Build an Electrical Emergency Kit

A well-prepared electrical emergency kit ensures you can respond quickly and safely during power outages or electrical hazards. Your kit should include flashlights with extra batteries, a battery-powered radio to stay informed, and portable chargers to keep essential devices powered. Add a fully stocked first-aid kit, an emergency contact list, and basic insulated tools for handling minor electrical issues safely. Including portable GFCI units can help prevent shock hazards when using temporary power sources, while fire-retardant blankets provide an extra layer of protection in case of small electrical fires.

What Industrial Facilities Should Add

Industrial facilities should add a comprehensive temporary power supply plan that outlines how operations will continue during outages, supported by accurate generator load calculations to ensure equipment can run safely and efficiently. A clearly defined priority equipment list helps determine which systems must receive power first, minimizing downtime and maintaining safety. Establishing an employee communication protocol ensures all staff receive timely updates and instructions during power disruptions. Additionally, maintaining clear lockout/tagout procedure sheets helps protect workers and equipment during maintenance or emergency operations, promoting a safe and organized response to unexpected power issues.

What NOT to Do During Electrical Emergencies

During electrical emergencies, it’s crucial to avoid several dangerous actions that can make the situation far worse. Never use candles during power outages since open flames can easily cause fires, especially in dark or cluttered areas. If an electrical fire breaks out, do not pour water on it—water conducts electricity and can lead to severe shocks or cause the fire to spread; instead, use a Class C fire extinguisher if available. Avoid repeatedly resetting a tripped breaker, as this can indicate a serious electrical problem that may lead to overheating or fire. Most importantly, never approach a fallen power line under any circumstances—treat all downed lines as live and keep a safe distance while contacting emergency services immediately.

Learning from Electrical Safety Incidents: Key Questions and Insights

Understanding past electrical safety issues is essential for preventing future incidents. Reflecting on these critical questions can help identify risks, improve safety protocols, and equip others to avoid similar challenges.

1. What Exactly Caused the Electrical Safety Issue?

Identifying the root cause is critical to preventing a recurrence. Common causes include:

- Faulty Wiring: Frayed or improperly installed wires are a frequent culprit.

- Overloaded Circuits: Exceeding the load capacity of an electrical system can lead to overheating and fires.

- Neglecting Safety Standards: Failure to adhere to electrical safety regulations during installation or maintenance can create vulnerabilities.

Example: An employee was using a remote control shopping cart trolley, and when he rolled the carts into the bay the cart trolley smashed sideways into the main 2500 amp circuit breaker.

This sudden side-blow caused the circuit breaker to trip (open), and shut down facility power – including the grocery store’s freezer section.

2. How Could This Electrical Safety Issue Have Been Avoided?

Most electrical incidents can be traced back to overlooked preventive measures. Here’s how you can avoid common issues:

- Proactive Maintenance: Regular inspections of wiring, outlets, and equipment can help detect wear and tear before it becomes hazardous.

- Proper Training: Ensuring all team members understand electrical safety guidelines and proper equipment usage reduces human error.

- Use of Safety Devices: Installing devices like protective barricades , GFCIs, surge protectors, and automatic shut-off systems can stop problems before they escalate.

3. How Much Worse Would This Electrical Safety Issue Have Been Without Quick Response?

Rapid responses often make the difference between a minor inconvenience and a major disaster.

- Damage Control: Quick action, like shutting off power to affected circuits, can prevent further damage to equipment and infrastructure.

- Life-Saving Measures: Prompt use of electrical safety equipment, such as fire extinguishers or insulated tools, can protect lives during an emergency.

Case Insight: In one scenario, a team identified sparking in an electrical panel early. Without their swift response, the issue could have escalated into a building-wide fire.

4. What Advice Would You Give to Others?

Lessons learned from one incident can provide valuable guidance to others. Key takeaways include:

- Develop an Electrical Safety Plan: Have a clear, actionable plan that includes emergency procedures and roles for all team members.

- Invest in Training: Conduct electrical safety training sessions tailored to your team’s environment, whether industrial, commercial, or residential.

- Perform Routine Safety Audits: Regularly review your systems and equipment to ensure they meet safety standards.

- Document Lessons Learned: Create a log of past incidents, including their causes, responses, and outcomes, to educate others and refine protocols.

Remember: Safety is not just about compliance; it’s about creating a culture where everyone understands and values preventive measures.

Why Electrical Safety Matters in Industrial Settings

Every industrial facility—from manufacturing plants to distribution centers—relies on uninterrupted electrical performance. But with high-voltage equipment, live panels, and time-sensitive operations, the risks can be significant.

Injuries caused by arc flashes, ungrounded circuits, or improper PPE don’t just cause personal harm—they can halt production and lead to costly fines.

By adopting simple steps like those listed above, electrical contractors and facility managers can:

Reduce equipment damage and costly downtime

Comply with OSHA and NFPA 70E regulations

Create a safety culture that protects everyone on site

Enhance Electrical Safety Awareness with Electrical Power & Control Consultants Inc.

Prioritizing safety doesn’t just protect lives—it preserves your investments and ensures compliance with safety regulations. Whether you’re looking for electrical safety training or need expert advice on electrical safety protocols, Electrical Power & Control Consultants Inc. is here to help.

Explore our range of industrial and commercial electrical components, designed to meet the highest safety standards, at Electrical Power & Control.

Stay Safe, Stay Powered!