Table of Contents

ToggleIn the world of industrial and commercial electrical systems, the layout of your electrical panel is more than just a matter of aesthetics—it’s a cornerstone of operational efficiency and safety. A well-planned electrical panel layout doesn’t just make your setup look professional; it directly impacts how easily your team can perform maintenance, how quickly issues can be diagnosed, and how effectively hazards are prevented.

Too often, electrical panels are treated as an afterthought—installed in a rush, overloaded with components, and left undocumented. This not only makes troubleshooting a headache but also increases the risk of accidents, non-compliance, and extended downtime. For maintenance technicians and facility managers alike, a chaotic panel layout can mean hours of unnecessary labor and exposure to serious safety risks.

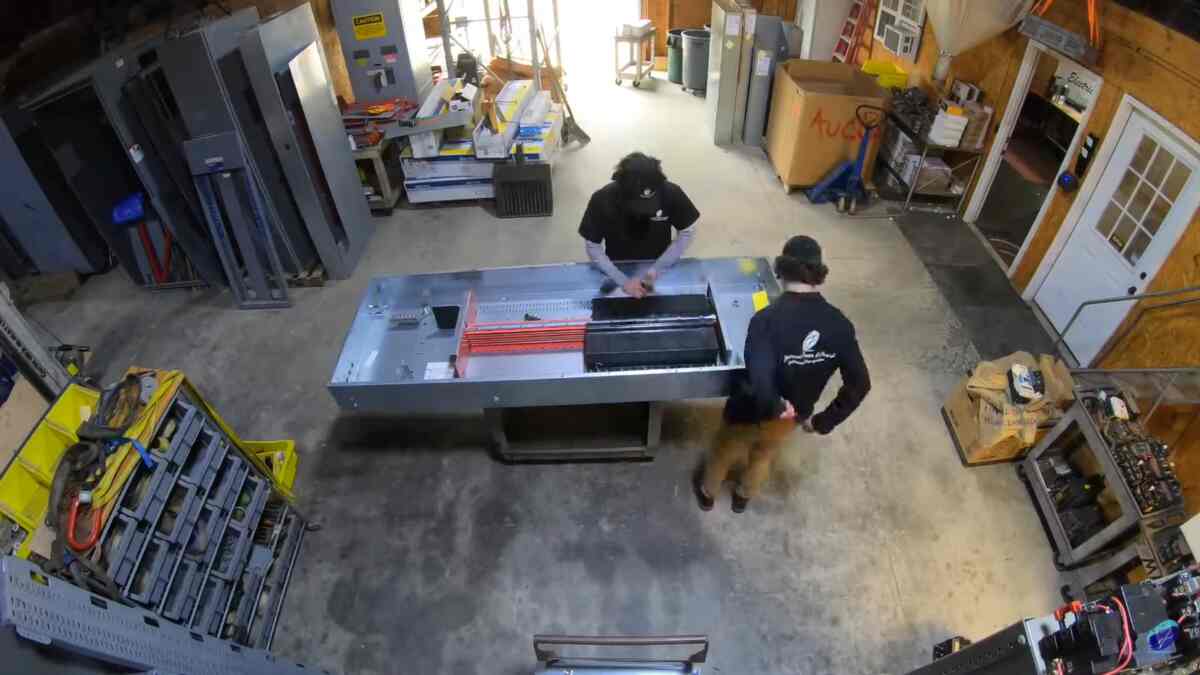

At Electrical Power and Control, we’ve seen firsthand how thoughtful design can transform a facility’s electrical infrastructure—from reactive and risky to proactive and reliable. In this guide, we’ll explore why electrical panel layout matters, how it ties directly to maintenance and safety, and what best practices you can implement to ensure your panels support, not hinder, your operations.

Let’s dive into the often-overlooked design decisions that can save you time, protect your team, and keep your systems running smoothly.

Understanding Electrical Panel Layout

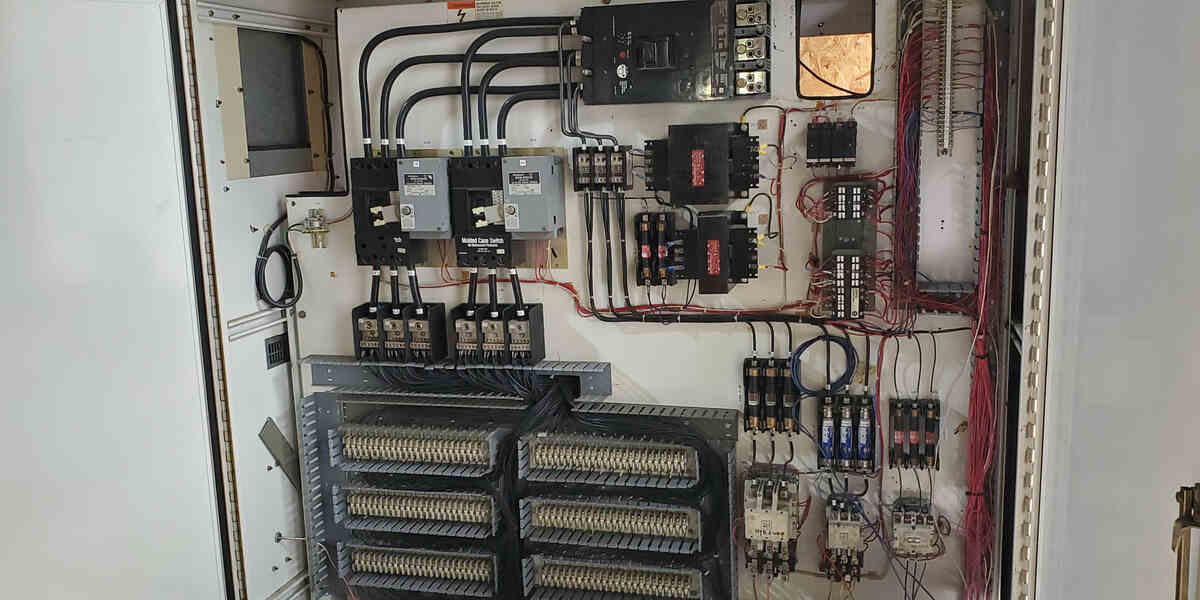

An electrical panel—also known as a breaker panel, distribution board, or control panel—is the central hub where incoming electrical power is distributed to various circuits throughout a facility. It’s the point of convergence for all wiring and protective devices, acting as both the brain and backbone of an electrical system.

Key Components of an Electrical Panel

Understanding the core components is essential before diving into the layout strategy. Typical panels include:

- Main Breaker: Controls power flow into the panel and provides emergency shutoff.

- Circuit Breakers or Fuses: Protect individual circuits from overcurrent.

- Bus Bars: Conductive strips that distribute power to breakers.

- Neutral and Grounding Bars: Manage return currents and safety discharges.

- Control Relays, PLCs, and Terminal Blocks: More common in industrial panels, they regulate machinery and manage wiring connections.

Each component plays a specific role, and their arrangement influences how safely and efficiently the panel can be serviced.

What Does “Layout” Really Mean?

Panel layout refers to the physical arrangement and grouping of components inside the enclosure. This includes:

- Component positioning: The logical and ergonomic placement of breakers, relays, and wiring paths.

- Spacing: Ensuring adequate clearance between components for heat dissipation and access.

- Wire routing: The organization and management of cables and connections.

- Labeling and documentation: Clearly identifying each element for quick reference.

Why Layout Matters From the Start

A clean, strategic layout isn’t just for the initial install—it sets the tone for the panel’s entire lifecycle. When designed intentionally, layouts:

- Improve troubleshooting speed by reducing time spent locating issues.

- Reduce human error during maintenance and upgrades.

- Support regulatory compliance by adhering to spacing and labeling standards.

- Enable future scalability, making it easier to expand or adapt systems later.

Whether you’re overseeing a multi-site facility or managing projects in the field, understanding layout fundamentals is the first step toward building safer, more efficient electrical systems.

The Link Between Layout and Maintenance Efficiency

When an electrical panel is thoughtfully laid out, routine maintenance becomes faster, safer, and far less disruptive. On the other hand, a poorly designed panel can turn even simple tasks, like replacing a breaker or diagnosing a tripped circuit, into a time-consuming process riddled with guesswork and risk.

Easier Troubleshooting Starts with Visual Clarity

Clear, organized layouts allow maintenance personnel to quickly trace circuits, identify components, and understand system flow. When labels are legible and components are logically grouped, technicians spend less time deciphering the panel and more time resolving the issue.

A cluttered or mislabeled panel, by contrast, forces teams to hunt through spaghetti-like wiring, increasing the chance of error and extended downtime. In industrial environments where every minute counts, that inefficiency directly affects the bottom line.

Reducing Downtime and Labor Costs

Efficient layouts reduce the number of steps required to perform maintenance tasks. This means:

- Faster diagnostics: Components are easier to access and test.

- Safer repairs: Clear paths and spacing reduce the risk of accidental contact.

- Streamlined documentation: Technicians can match physical layout with schematics and panel schedules more accurately.

For example, when terminal blocks are grouped by function and wire markers are consistent, isolating a faulty sensor or actuator becomes a matter of minutes, not hours.

A Real-World Perspective

Consider “Contractor Carl,” an electrical contractor managing multiple system installations on tight timelines. For Carl, disorganized panels mean rework, return visits, and frustrated clients. When a panel is laid out with serviceability in mind, he’s able to complete inspections, handoffs, and troubleshooting with confidence and speed.

Similarly, “Industrial Ingrid”—a facility manager responsible for keeping operations online—relies on accessible, clearly labeled panels to execute preventive maintenance and avoid unplanned shutdowns. A clean layout supports her team’s efficiency and reduces their exposure to hazardous conditions.

Ensuring Safety Through Proper Layout

A well-designed electrical panel does more than simplify maintenance—it’s a frontline defense against hazards that can lead to injuries, equipment damage, and costly downtime. When layout is neglected, safety risks multiply. But when done right, layout becomes a critical part of a facility’s safety strategy.

Aligning with Safety Standards

Compliance with recognized safety standards such as NFPA 70E, OSHA, and UL 508A is not optional—it’s essential. These codes govern aspects like:

- Clearances and spacing between live parts and grounded surfaces

- Labeling and warning signage

- Access to disconnects and breakers

- Protection against arc flash and electrical shock

A clean, organized layout makes it easier to design and maintain compliance. For example, proper spacing helps meet minimum approach distances, while clear labels assist in lockout/tagout (LOTO) procedures.

Reducing the Risk of Arc Flash and Other Hazards

Arc flash incidents can be catastrophic, resulting in severe injuries or fatalities. Improper panel layout—such as overcrowded components, tangled wiring, or unsecured terminations—increases the likelihood of an arc flash event.

Here’s how a smart layout reduces this risk:

- Separation of high-voltage and control circuits prevents unintended contact or shorts.

- Secure cable routing minimizes wear from vibration and heat.

- Component derating and spacing help reduce thermal buildup, which is a precursor to electrical failure.

These layout practices, when paired with proper PPE and work procedures, significantly enhance workplace safety.

Accessibility Saves Lives

Safety isn’t just about preventing incidents—it’s also about responding effectively when something goes wrong. In emergencies, technicians need fast access to:

- Main breakers or disconnects

- Fault indicators or alarms

- Clear identification of circuits and devices

A poorly arranged panel delays these actions, potentially turning a minor fault into a major event. That’s why layout decisions should always be made with emergency response in mind.

Best Practices for Electrical Panel Layout

Designing an effective electrical panel layout isn’t just about fitting components into an enclosure—it’s about creating a system that’s logical, maintainable, and safe. Here are proven best practices that professionals like Contractor Carl and Industrial Ingrid rely on to ensure efficient and reliable installations.

Group Components by Function

Organize internal components based on their function (e.g., power supply, motor control, safety relays, PLCs). This not only makes troubleshooting easier but also allows future technicians to intuitively understand the system flow.

- Why it matters: Functional grouping enables fast isolation of faults and improves clarity when cross-referencing with schematics.

- Tip: Use labeled partitions or color-coded backplates to visually distinguish sections.

Prioritize Wire Management

Wire clutter is a common issue that leads to misdiagnosis, increased repair time, and overheating. Use dedicated wire ducts, tie-downs, and routing channels to keep everything in place.

- Do: Route wires in straight paths with 90-degree angles for easy tracing.

- Avoid: Letting cables dangle or overlap across devices unnecessarily.

Label every wire at both ends using standardized markers—this small investment can save hours during future repairs.

Maintain Adequate Spacing

Proper spacing between components ensures sufficient airflow and prevents overheating. It also allows room for test leads, meter probes, and tools during inspections.

- Reference: Follow UL 508A and manufacturer guidelines for minimum spacing.

- Pro Tip: Expansion plan—leave open slots and flexible mounting space.

Clear, Consistent Labeling

Consistent labeling turns a maze into a map. Every breaker, relay, wire, and terminal block should be clearly marked and documented in the panel schedule.

- Best practices:

- Use engraved or printed labels for durability.

- Mirror labeling across the panel and the electrical schematic.

- Color code labels where appropriate (e.g., red for emergency circuits).

- Use engraved or printed labels for durability.

Design for Access and Serviceability

Consider how technicians will interact with the panel post-installation. Place high-use items (like breakers or disconnects) near the front and at accessible heights.

- Avoid: Placing critical components behind wiring bundles or in corners that require dismantling to access.

- Think long-term: Add hinged doors, swing panels, or removable plates where extra depth is needed.

Standardize Layouts Across Panels

For companies managing multiple facilities or systems, consistency across panels improves training, auditing, and maintenance.

- Create layout templates or CAD standards.

- Maintain a “panel layout handbook” with examples and layout logic.

- Collaborate across departments to align expectations (engineering, safety, maintenance).

Use Layout Software & Digital Tools

Modern panel design software like AutoCAD Electrical, EPLAN, or SolidWorks Electrical streamlines layout planning, helps simulate routing, and ensures compliance from the outset.

- Bonus: Many tools now integrate with ERP and inventory systems to streamline part procurement and documentation.

Integrating Layout Considerations in the Design Phase

The best time to address panel layout isn’t during installation or commissioning—it’s during the design phase. By planning early, project teams can avoid costly rework, enhance safety, and ensure that the panel aligns with long-term operational needs.

Design with the End User in Mind

Panel layouts should be designed not only for electrical function, but also for the technicians and engineers who will maintain them. This includes considering:

- Who will service the panel? Maintenance teams may need more space or visibility than installers.

- What’s the operating environment? Harsh conditions like heat, dust, or vibration require special layout strategies (e.g., sealed enclosures, vibration-resistant components).

- How often will changes be needed? If future upgrades are likely, design for modularity and space.

Thinking from the end user’s perspective leads to smarter decisions about component placement, accessibility, and documentation.

Collaborate Across Departments

Effective layout design requires input from multiple stakeholders:

- Engineering: Ensures proper function and spec compliance.

- Maintenance: Offers insights on accessibility and common failure points.

- Procurement: Helps standardize parts and manage lead times.

- Safety/Compliance Officers: Ensures the layout supports inspection and regulatory readiness.

A collaborative approach creates panels that are not only code-compliant but also highly functional in the field.

Leverage Digital Tools and Simulations

Using design software like AutoCAD Electrical or EPLAN enables teams to build detailed layouts before a single wire is cut. These tools offer:

- 3D visualization of component spacing and door clearance

- Wiring simulations to identify congestion or overlaps

- Integration with part catalogs for easier BOM (Bill of Materials) creation

Digital-first design also streamlines approvals, troubleshooting, and change management.

Build for Flexibility and Scalability

Facilities evolve. Machines are upgraded. New sensors and controllers are added. A good panel layout allows for easy expansion without total rework.

- Include extra DIN rail space and spare terminal blocks.

- Document unused ports or connections.

- Label open positions for future use.

By designing with change in mind, you’re not just building a panel—you’re building a platform that can grow with the operation.

Common Mistakes to Avoid

Even experienced professionals can overlook key elements when pressure mounts during installation or retrofitting. Here are some of the most common mistakes in electrical panel layout—and how to avoid them.

Overcrowding Components

Trying to “fit it all in” might save enclosure space in the short term, but it often creates more problems than it solves.

- Risks: Poor airflow, difficult access, increased heat buildup, and non-compliance with UL/NFPA spacing requirements.

- Solution: Choose an appropriately sized enclosure and plan for at least 20–30% future expansion. Prioritize breathing room over compactness.

Neglecting Ventilation and Heat Dissipation

Heat is the silent killer of electrical components. Panels crammed full of high-load devices without airflow considerations are prone to premature failure.

- Risks: Shortened lifespan of components, nuisance tripping, and elevated fire hazards.

- Solution: Use vented enclosures or install fans/heat exchangers. Keep heat-generating devices away from each other and monitor internal temperatures in harsh environments.

Poor or Missing Labeling

Unlabeled or inconsistently labeled components confuse technicians and introduce the risk of incorrect servicing.

- Risks: Longer downtimes, safety violations, and failed inspections.

- Solution: Standardize labeling from the outset. Use clear, durable markers for breakers, relays, terminals, and wire ends. Match all labels to the corresponding schematics.

Inconsistent Wiring Practices

Loose, tangled, or undocumented wiring creates chaos inside the enclosure.

- Risks: Increased troubleshooting time, elevated chance of cross-connections, and higher risk of accidental shorts.

- Solution: Follow standardized routing paths, use wire markers at both ends, and tie cables securely in harnesses or ducts.

Ignoring Accessibility

Installing components where they’re hard to reach—such as behind wires, above head height, or deep inside the cabinet—makes future maintenance far more difficult.

- Risks: Slower service, higher labor costs, and increased technician risk.

- Solution: Always consider reach, visibility, and tool clearance. Place high-use items like breakers and disconnects at chest height and unobstructed.

Skipping Documentation

Even the best layout loses value without updated documentation. Panels evolve, and if changes aren’t recorded, future work becomes a guessing game.

- Risks: Unrecorded modifications, wasted time, and increased likelihood of mistakes.

- Solution: Maintain a current panel schedule, wiring diagrams, and layout drawings—ideally both printed inside the panel door and stored digitally.

Conclusion

A thoughtfully designed electrical panel layout is more than a mark of professionalism—it’s a vital investment in the safety, efficiency, and longevity of your entire electrical system. Whether you’re managing high-pressure industrial operations or overseeing tight project timelines, the panel layout you choose today directly impacts how your team will maintain and rely on that system tomorrow.

From organizing components and planning wire routes to ensuring compliance with safety standards, every decision made during the design and installation process contributes to easier maintenance, reduced risk, and fewer headaches down the line.

At Electrical Power and Control, we understand what’s at stake. With over 25 years of industry experience and a commitment to tailored, high-quality solutions, we help professionals like you build panels that are dependable, scalable, and built for the long haul.

Need a Custom Electrical Panel? If you’re planning a new facility, upgrading an aging system, or simply need help designing a layout that puts safety and serviceability first, we’re here to help. Contact Electrical Power and Control at (205) 812-5402 to speak with our team about your custom electrical panel requirements. Your operation deserves a panel that works as hard as you do.