Table of Contents

ToggleIf you’re wondering what to do in the event of power loss—especially during a public or corporate event—you’re not alone. Power failures can bring everything to a halt, endanger guest safety, damage equipment, and create panic if not handled properly. The key is to act quickly, stay calm, and follow a clear emergency plan.

So, what should you do when the power goes out?

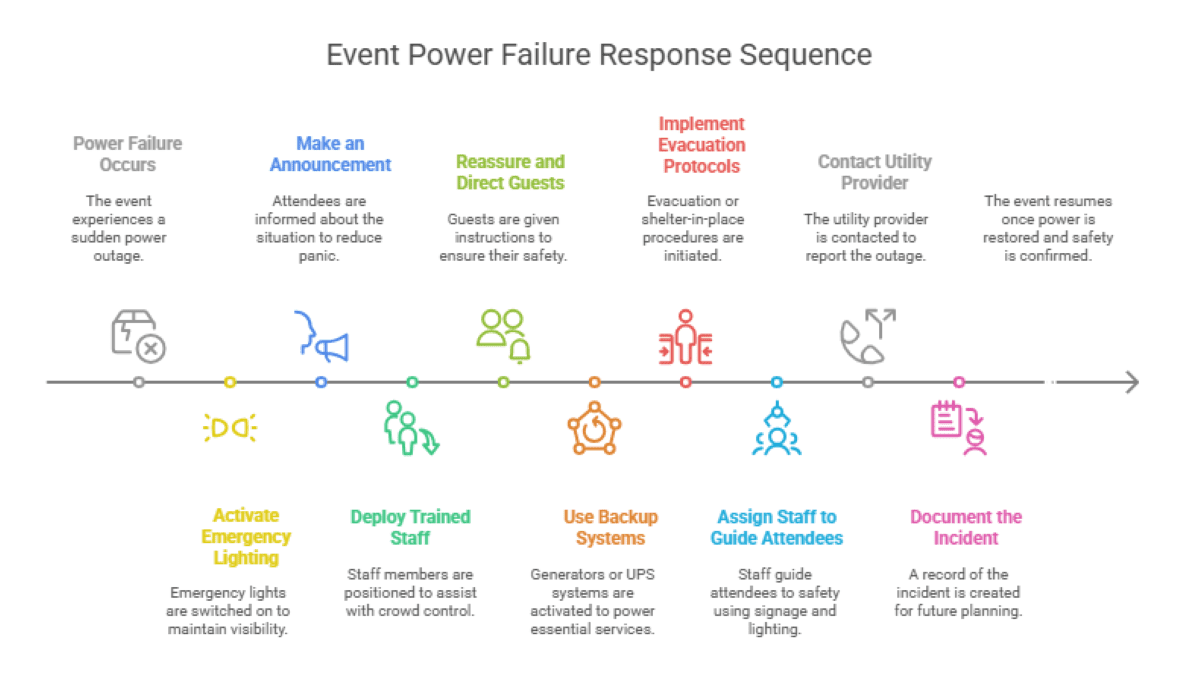

First, ensure immediate safety by switching to emergency lighting and communicating with attendees. Then, activate any available backup systems—like generators or UPS units—and deploy trained staff to manage crowd control and maintain order. If your event setup includes critical systems (AV, security, or temperature control), prioritize stabilizing those components. Document the incident and coordinate with utility providers to restore power as efficiently as possible.

If your event is ongoing and conditions are unsafe, you may need to pause or evacuate. But with a solid plan, most situations can be managed smoothly—even during a total blackout.

Power failure in events isn’t just an inconvenience—it’s a serious operational challenge. This article will walk you through everything you need to know: from understanding the most common causes of outages, to safety tips, emergency tools, and long-term planning for your business or venue.

Whether you’re preparing for a future event or responding in real time, the steps outlined here will help you protect your guests, your team, and your operations. Let’s start with the most common causes of power outages—and how you can anticipate and address them.

Common Causes of Power Outages and Failures

Understanding the root causes of power loss is the first step in preventing it. Power failures—whether short or extended—can occur due to a variety of factors. Being aware of these can help you plan better, respond faster, and minimize the impact on your operations or events.

- Weather-Related Disruptions

- Storms, high winds, lightning, flooding, and ice can damage power lines, transformers, and other infrastructure, leading to widespread electrical power interruptions.

- Utility Grid Issues

- Sometimes the problem isn’t local. Failures within the utility provider’s grid—like equipment overloads, aging infrastructure, or substation failures—can cause blackouts across large areas.

- Equipment Failure

- A malfunction in your own facility or event setup can trip circuits or shut down systems entirely. Overloaded circuits, old wiring, or faulty panels are common culprits behind localized outages.

- Human Error

- Accidental power shut-offs, mishandling of electrical systems, or construction-related damage to underground lines can all lead to power disruptions.

By understanding these causes of power failure, you can better design safeguards, build redundancy into your systems, and train your team for faster recovery when outages strike.

General Safety Measures During a Power Outage

When the power goes out, safety comes first. Whether you’re at home, in a commercial facility, or managing a public event, these power outage safety tips can help protect both people and property.

- Turn off and unplug electronics

Unplug sensitive devices and turn off appliances to prevent damage from sudden power surges when electricity returns. - Avoid using open flames

Do not rely on candles for light. They increase the risk of fire, especially in crowded or emergency scenarios. Use safer alternatives like battery-powered lighting. - Use battery-powered lighting

Keep flashlights, lanterns, or headlamps ready. Choose LED options for energy efficiency and long-lasting brightness. - Stay informed with a battery-powered radio

Use a weather or emergency radio to receive updates if the internet or cell service is unavailable. - Preserve food and water supplies

Keep refrigerator and freezer doors closed to maintain temperature. Store bottled water and non-perishable food for extended outages.

Taking these precautions helps ensure personal safety, minimizes hazards, and keeps operations secure until power is restored.

What to Do in the Event of Power Failure at Events

A power failure in an event setting—whether it’s a concert, conference, or corporate gathering—can quickly become a safety and logistical nightmare. The key is having a clear plan that kicks in immediately. Here’s how to respond effectively and keep your event safe, organized, and under control.

Immediate Actions During the Event

- Activate emergency lighting

Switch to battery-powered or generator-backed lighting to maintain visibility and prevent accidents. - Make an announcement

Calmly inform attendees of the situation using the public address system (if still functioning) or a megaphone. Clear communication reduces panic. - Deploy trained staff or your emergency response team

Designated personnel should take their positions to assist with crowd control, guide guests, and handle any developing issues. - Reassure and direct guests

Provide simple, reassuring instructions to attendees. Let them know that safety protocols are in place and being followed.

Backup Systems & Contingency Planning

- Use generators or UPS (Uninterruptible Power Supply) systems

These can power essential systems like lighting, sound, and security until full power is restored or evacuation is complete. - Implement evacuation or shelter-in-place protocols

Your emergency plan should account for different scenarios and provide clear directions depending on the nature and length of the outage. - Test backup systems regularly

Ensure all emergency power systems are maintained and tested before every major event.

Crowd Control & Safety

- Assign staff to guide attendees

Trained personnel should be stationed at key points to direct people safely. - Use signage and emergency lighting

Illuminated exit signs, glow-in-the-dark tape, or portable lighting systems help guests find their way even in complete darkness. - Keep all exits accessible

Make sure exits are clear and not blocked by equipment, furniture, or crowds.

Restoring Order & Power

- Contact your utility provider or on-site technician

Report the outage and gather information about resolution timelines. - Document the incident

Keep records of what happened, how it was handled, and any lessons learned for future planning. - Restart event procedures when safe

If and when power is restored, resume the event only after confirming all systems are functioning and it’s safe to proceed.

Power failures don’t have to mean chaos. With preparation and trained personnel, even unexpected outages can be managed smoothly and professionally.

How Businesses Can Prepare for Future Outages

While power outages are often unpredictable, your response to them doesn’t have to be. For industrial facilities, commercial buildings, and event organizers, preparation is key to minimizing downtime and maintaining safety. Here’s how to be proactive before the next blackout strikes.

- Conduct a power failure risk assessment

Evaluate your facility or venue to identify critical systems, weak points, and the potential impact of a power loss. - Install generators and test them monthly

Backup generators should be sized appropriately for your needs and tested regularly to ensure they’re ready when needed. - Train employees on emergency response protocols

Every team member should know what to do during a power outage—whether that means shutting down equipment safely or guiding guests to exits. - Develop a blackout response plan

Create a step-by-step guide that outlines how to secure operations, communicate with stakeholders, and restore normalcy during and after an outage. - Establish vendor and utility contacts in advance

Keep contact information for electricians, utility providers, and emergency suppliers easily accessible.

Preparing ahead not only keeps people safe—it also protects your business operations, reputation, and bottom line.

Emergency Kits & Tools for Power Loss

Having the right tools and supplies on hand can make all the difference during a power outage. Whether you’re operating a facility or hosting a public event, a well-stocked emergency kit helps ensure safety, comfort, and readiness.

- Flashlights and lanterns

Keep multiple battery-powered or rechargeable LED flashlights and lanterns available. Avoid open flames and ensure devices are easily accessible. - Extra batteries and portable chargers

Store plenty of extra batteries in various sizes. Include power banks to keep phones and small devices charged during prolonged outages. - First aid kits

Every emergency plan should include a complete first aid kit with bandages, antiseptics, gloves, and any essential medications. - Non-perishable food and water

Stock bottled water and shelf-stable foods like canned goods, granola bars, and dry snacks for employees or attendees if sheltering in place becomes necessary. - Warm blankets and weather protection

Include blankets, ponchos, and hand warmers—especially for colder climates or seasons. Comfort and warmth are vital during extended blackouts. - Communication and lighting tools

Battery-powered radios, whistles, emergency beacons, and glow sticks can all help maintain communication and visibility when other systems fail.

Keeping these essentials organized and regularly checked ensures you’re always ready to respond quickly and safely when the power goes out.

When to Seek Professional Help

Not all power issues can be handled in-house. Knowing when to call in a professional can prevent further damage, ensure safety, and get your systems back online faster.

- After unusual power surges or flickering

If you notice lights dimming, electronics resetting, or frequent breaker trips, it may indicate deeper electrical issues. Don’t ignore the signs—schedule an inspection. - When there’s physical damage to your electrical system

Burnt outlets, frayed wires, or exposed panels are hazards that should be addressed by a licensed electrician immediately. - If backup systems fail to start

Generators or UPS units that don’t activate during an outage may need repair or replacement. A professional can diagnose the issue and restore reliability. - When safety is in question

If you’re unsure whether your environment is safe to resume operations, bring in a qualified expert for a full system check. - During restoration of large-scale event systems

For venues and event organizers, power restoration isn’t just about flipping a switch. Let certified technicians verify system integrity before resuming activities.

Electrical failures can pose serious risks if not handled properly. Don’t hesitate to bring in expert help when needed—it’s the fastest and safest path to recovery.

Conclusion

Power outages are more than just an inconvenience—they can impact safety, disrupt operations, and cause lasting damage if not handled properly. Whether you’re managing a facility or hosting a large-scale event, being proactive is the best defense.

From understanding what to do in the event of power loss, to creating response protocols for power failure in events, preparation empowers you to protect people, prevent chaos, and resume operations faster. If you’re ready to upgrade your power backup systems or want expert guidance on your emergency preparedness plan, contact Electrical Power & Control—your trusted partner in electrical reliability and custom solutions.