Table of Contents

ToggleWhen you’re managing a facility or leading a high-stakes electrical project, reliability isn’t optional—it’s everything. One unexpected surge, and the entire operation can grind to a halt. That’s where circuit breakers come in: they’re the silent guardians of your power infrastructure.

A circuit breaker isn’t just another component in an electrical panel—it’s a first line of defense for equipment, uptime, and safety. Whether you’re an electrical contractor racing against project deadlines or a facility manager juggling maintenance schedules, the right circuit breaker can mean the difference between smooth operations and costly disruptions.

At Electrical Power and Control, we’ve spent over 25 years helping professionals like you source the exact breakers they need—on time, up to code, and built to last. This guide breaks down everything you need to know about circuit breakers: how they work, the types you’ll encounter, how to choose the right one, and how emerging technologies are reshaping the industry.

Let’s get started—because better decisions today lead to fewer emergencies tomorrow.

What Is a Circuit Breaker and How Does It Work?

A circuit breaker is a critical safety device designed to detect and interrupt the flow of electrical current when it exceeds safe operating conditions. Think of it as your electrical system’s first responder—cutting off power in milliseconds to prevent fires, equipment damage, and costly downtime.

In industrial and commercial environments—where voltage levels are higher, current demand is heavier, and the stakes are much greater—circuit breakers play an even more vital role in ensuring safety, compliance, and operational continuity.

The Role of a Circuit Breaker in Your Power System

When electrical current flows normally, the circuit breaker allows uninterrupted power transmission. But when an overcurrent, short circuit, or ground fault occurs, the breaker automatically “trips” (i.e., opens the circuit), cutting off the flow of electricity. This protects not just the immediate equipment, but the entire system downstream.

Without this mechanism, a single fault could cascade, resulting in electrical fires, equipment failures, or even injuries on the job site.

How Circuit Breakers Detect Faults

Most breakers use one or more of the following mechanisms to sense danger:

Thermal Protection (Overload Protection)

- Uses a bimetallic strip that bends as it heats up due to sustained high current.

- Once the strip bends far enough, it triggers the trip mechanism.

- Ideal for detecting slow-building overloads, such as drawing too much current over time, common in HVAC units, motor control centers (MCCs), and lighting circuits.

Magnetic Protection (Short Circuit Protection)

- Responds instantly to a sudden surge in current.

- A solenoid coil creates a magnetic field strong enough to flip the internal switch open.

- Essential in environments where sudden faults—like accidental shorts during installation—can cause devastating arc flash incidents.

Electronic (Digital) Protection

- More advanced breakers (especially MCCBs and ACBs) use electronic trip units that monitor current digitally.

- These provide precision, adjustability, and data logging, making them ideal for system integrators managing smart or IoT-enabled electrical systems.

Circuit Breakers vs. Fuses: What’s the Difference?

While both fuses and circuit breakers serve to protect electrical systems from overcurrent conditions, they do so in fundamentally different ways. A fuse is a one-time-use device: when excessive current flows through it, the metal wire inside melts, physically breaking the circuit. Once a fuse blows, it must be replaced.

Circuit breakers, on the other hand, are resettable. After tripping in response to a fault, they can be manually or automatically reset, without the need for part replacement. This makes circuit breakers more cost-effective and convenient, especially in systems that require frequent access or are prone to transient faults.

In terms of maintenance and diagnostics, breakers also have the edge. Many offer visual indicators or digital feedback that shows exactly when and why a trip occurred, while fuses often leave you guessing until you test or inspect each one. Because of these benefits, circuit breakers are now the industry standard in most modern electrical systems, especially in commercial and industrial facilities where reliability and uptime are critical.

The Benefits of Circuit Breakers in Industrial Environments

- Prevents cascading failures by isolating faults quickly.

- Reduces downtime with quick resets and minimal component replacement.

- Improves safety for personnel and infrastructure.

- Supports code compliance with UL, IEC, NEC, and NFPA 70E standards.

- Simplifies troubleshooting with clear trip indicators or digital fault data.

Whether you’re designing a new panelboard or upgrading an aging infrastructure, understanding how circuit breakers work helps you make smarter, safer decisions for every application.

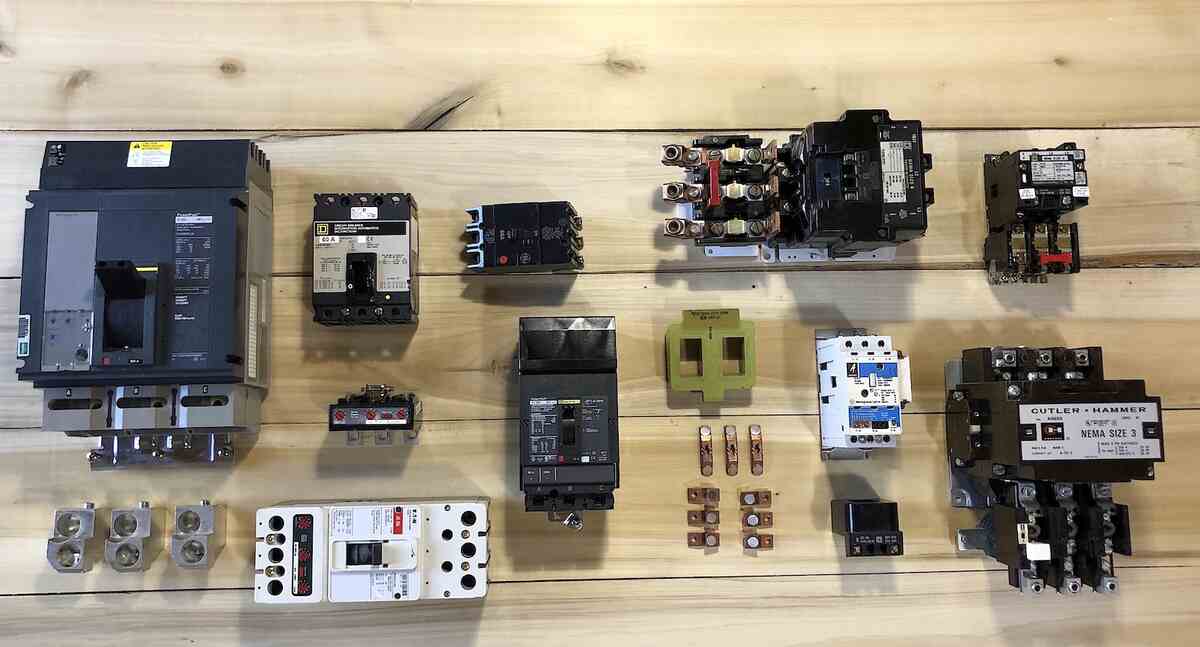

Classifications of Circuit Breakers

Not all circuit breakers are created equal. The type you choose depends on the system voltage, the nature of the load, environmental conditions, and the level of protection required. In industrial and commercial settings—where precision and reliability are non-negotiable—it’s crucial to understand how circuit breakers are classified. Below, we break it down into four primary frameworks used to categorize circuit breakers.

By Voltage Class

Voltage classification determines the physical construction, insulation requirements, and arc-quenching methods of the breaker. Here’s how they’re grouped:

- Low-Voltage Circuit Breakers (LVCBs): Rated up to 1,000 volts AC, these are commonly used in control panels, switchboards, and motor control centers. Typical examples include Miniature Circuit Breakers (MCBs) and Molded Case Circuit Breakers (MCCBs).

- Medium-Voltage Circuit Breakers (MVCBs): Operating between 1kV and 72.5kV, these breakers are found in industrial switchgear and substations. They usually employ vacuum or SF₆ gas as an arc-extinguishing medium.

- High-Voltage Circuit Breakers (HVCBs): Used in transmission systems above 72.5kV, these breakers often rely on sophisticated insulation and remote control systems. Their design accommodates higher arc energy and longer insulation distances.

Understanding the voltage class is the first step in choosing a breaker that’s safe and compliant for your system.

By Arc Interruption Medium

How a circuit breaker extinguishes the electrical arc is vital for performance and safety. Industrial applications require reliable arc-quenching to minimize downtime and damage:

- Air Circuit Breakers (ACBs): Use air as the arc-quenching medium and are typically found in low-voltage distribution systems. They’re favored for their ease of maintenance and accessibility.

- Oil Circuit Breakers: Use oil to cool and quench the arc. While effective, they require frequent maintenance and are being phased out due to environmental concerns and safety risks.

- Vacuum Circuit Breakers (VCBs): These use a sealed vacuum chamber where the arc is quickly extinguished. VCBs are ideal for medium-voltage indoor applications due to their durability and low maintenance needs.

- SF₆ Circuit Breakers: Filled with sulfur hexafluoride gas, these breakers are widely used in high-voltage systems due to their superior insulation and arc-quenching abilities. However, environmental regulations are prompting a shift toward greener alternatives.

Choosing the right arc-interruption technology impacts both safety and maintenance costs, especially in demanding environments.

By Application or Use

Different loads and conditions call for specialized breaker designs:

- Miniature Circuit Breakers (MCBs): Typically rated below 100 amps, MCBs are used for lighting and small appliance circuits. They’re compact, reliable, and commonly found in residential and light commercial systems.

- Molded Case Circuit Breakers (MCCBs): Handle higher loads and offer adjustable trip settings. Ideal for industrial panels and machinery.

- Ground Fault Circuit Interrupters (GFCIs): Detect ground faults and shut off power to prevent shock. Often used in wet areas like wash-down stations or outdoor control panels.

- Arc Fault Circuit Interrupters (AFCIs): Detect electrical arcs that traditional breakers might miss—an added layer of fire protection in sensitive environments.

- DC Circuit Breakers: Specifically designed to interrupt direct current. Essential in solar installations, battery systems, and uninterruptible power supplies (UPS).

- Generator Circuit Breakers: Installed between generators and step-up transformers to handle high fault currents and prevent reverse power flow.

Knowing which breaker to use isn’t just about current ratings—it’s about matching the breaker’s features to the job at hand.

By Pole Configuration

The number of poles determines how many conductors the breaker can isolate and control:

- Single-Pole Breakers: Control one hot wire and are used in 120V systems.

- Double-Pole Breakers: Control two hot wires and are used in 240V systems. Common in HVAC, water heaters, and larger machinery.

- Three-Pole Breakers: Essential in 3-phase industrial systems—used for motors, pumps, and high-load equipment.

In industrial facilities, pole configuration affects not only safety but also system balancing and troubleshooting ease.

Understanding these classification types allows you to specify or source the right breaker, whether you’re building out a new MCC, upgrading an existing panel, or troubleshooting recurring faults in a production facility. Getting it wrong can lead to nuisance tripping, non-compliance, or worse, unexpected downtime.

Common Use Cases in Industrial and Commercial Systems

Circuit breakers are more than just protective devices—they’re strategic components that help ensure uninterrupted operations, regulatory compliance, and personnel safety across a wide range of environments. For industrial manufacturers, commercial facilities, and system integrators, understanding how and where different circuit breakers are used can streamline design, improve maintenance, and reduce costly downtime.

Let’s look at some of the most common use cases tailored to the challenges and workflows of your key stakeholders.

For Electrical Contractors and System Integrators

Teams in the field often operate under tight deadlines and complex client specifications. In these projects, reliability, speed of delivery, and proper component selection can make or break timelines. This is where circuit breakers typically play a vital role:

- Panelboard Installations: MCBs and MCCBs are used to provide overcurrent protection for lighting, HVAC, and receptacle circuits in commercial buildings. The right selection ensures code compliance and simplifies future expansion.

- Switchgear Design: For larger systems, contractors specify ACBs or VCBs based on load requirements, short-circuit ratings, and coordination plans. Using smart or adjustable breakers supports downstream protection and remote diagnostics.

- Motor Control Centers (MCCs): MCCBs and electronic breakers provide overload and short-circuit protection for motors and automation equipment, with adjustable trip units to support different startup curves.

- Temporary Power Systems: Portable panelboards or generator hookups often require durable, field-resettable breakers rated for rugged environments and variable loads.

For Facility Managers and Industrial Operators

Minimizing equipment downtime while managing aging infrastructure with limited budgets is a constant challenge. The strategic use of circuit breakers plays a direct role in helping teams stay proactive, not reactive:

- Feeder Breakers for Equipment Zones: MCCBs or HVCBs isolate equipment bays or production lines, allowing selective shutdowns without impacting the entire plant.

- Breaker-Based Maintenance Isolation: Lockable breakers provide safe, code-compliant isolation points for servicing equipment during preventive or emergency maintenance.

- Power Distribution Panels: Breakers here ensure power is routed reliably to essential systems—like compressed air, conveyors, or robotics—without interruption or overload risks.

- Environmental Controls: AFCIs and GFCIs may be required in areas with moisture or flammable materials to reduce fire and electrocution hazards.

- Backup Power Systems: Generator circuit breakers protect both the generator and the connected systems during startup, load transfer, or reverse feeding.

Use Case Tip

No matter the project type, choosing the right breaker often comes down to balancing protection with operational flexibility. Coordinated tripping (selective coordination), remote monitoring, and easy reset capabilities are increasingly becoming non-negotiables in mission-critical environments.

Whether it’s a food plant, a data center, or a construction site, circuit breakers play a crucial role in delivering uptime, safety, and operational resilience.

How to Choose the Right Circuit Breaker

Choosing the right circuit breaker isn’t just about matching amperage ratings, especially in industrial and commercial environments where electrical systems are complex and failure is expensive. The ideal breaker must fit the application’s technical requirements, meet compliance standards, and support long-term operational reliability.

Here’s a step-by-step breakdown to help contractors, engineers, and facility managers make informed decisions.

Determine System Requirements

Start by identifying the electrical parameters of the system:

- Voltage Rating: Ensure the breaker can handle the system’s operating voltage (e.g., 480V for many industrial setups).

- Current Rating (Amperage): Match the breaker’s continuous load rating to the load it will protect—oversizing can compromise protection; undersizing will lead to nuisance tripping.

- Interrupting Rating (AIC): Choose a breaker with a short-circuit interrupt rating that meets or exceeds the available fault current at the point of installation.

Select the Appropriate Trip Curve

Different loads behave differently under fault conditions. Circuit breakers use trip curves to define how quickly they respond:

- Type B: Trips at 3–5 times rated current (for residential/light commercial)

- Type C: Trips at 5–10 times rated current (for most commercial and industrial loads)

- Type D: Trips at 10–20 times rated current (for motors and heavy inductive loads)

Understanding the startup behavior of your equipment (e.g., motor inrush current) will prevent unnecessary trips.

Choose the Right Breaker Type

Match the breaker to the application and environment:

- MCB for lower load residential or small commercial circuits.

- MCCB for industrial equipment, feeders, and motors.

- ACB for large distribution systems requiring adjustable protection and remote monitoring.

- VCB or SF₆ Breaker for medium to high voltage systems requiring superior arc extinction.

- Electronic breakers with digital trip units for smart grid or remote-integrated systems.

Consider Environmental and Application Conditions

Breakers must perform reliably in their intended environments:

- Ambient Temperature: Breakers are rated at 40°C by default. For high-heat areas (e.g., near furnaces or roof-mounted panels), derating may be necessary.

- Moisture or Dust Exposure: Use breakers housed in NEMA-rated or IP-rated enclosures for protection.

- Hazardous Locations: Install explosion-proof or intrinsically safe breaker assemblies if required by code.

Ensure Code Compliance

Depending on your jurisdiction and project type, breakers must comply with:

- NEC (National Electrical Code) or CEC (Canadian Electrical Code)

- UL/CSA/IEC standards for product listing and testing

- NFPA 70E requirements for arc flash labeling and safe work practices

Working with a trusted supplier—like Electrical Power and Control—ensures your selected breakers meet local and national standards, helping avoid inspection issues and legal liability.

Think About Maintenance and Monitoring

For system integrators and facility managers, ongoing visibility and serviceability are critical:

- Breakers with status indicators or trip diagnostics simplify troubleshooting.

- Remote monitoring allows for predictive maintenance and performance alerts.

- Modular, field-replaceable breakers reduce downtime during repairs or upgrades.

Quick Checklist for Selection:

- What is the system voltage and fault current?

- What’s the continuous load the breaker will protect?

- Is the breaker curve appropriate for the load type?

- Does it meet local code and environmental requirements?

- Will it support future maintenance or upgrades?

The right circuit breaker does more than protect—it empowers operational efficiency and peace of mind.

Installation and Testing Best Practices

Proper installation and regular testing of circuit breakers are essential to ensuring electrical safety, system reliability, and long-term compliance. Whether you’re building a new distribution system, retrofitting an existing panel, or performing preventive maintenance, following best practices helps reduce risk, improve uptime, and extend equipment life.

Here’s what contractors, facility managers, and system integrators need to keep in mind during installation and ongoing maintenance.

Breaker Installation: What to Do and What to Avoid

- Verify Ratings Before Installation

Always double-check voltage, amperage, and interrupting capacity against system specs. Installing a breaker with an insufficient AIC rating can be a catastrophic liability. - Torque Connections Properly

Loose or over-tightened terminals can lead to overheating or arcing. Use a calibrated torque wrench and follow the manufacturer’s specifications exactly. - Observe Line and Load Orientation

Especially in MCBs and MCCBs, reversing line/load connections can compromise the breaker’s trip functionality or void warranty. - Maintain Proper Phase Separation

Use phase barriers, terminal covers, and proper spacing to prevent accidental contact or arc flash risks, especially in high-voltage panels. - Label Clearly and Consistently

All breakers should be labeled with their load destination and trip settings. Use engraved or adhesive labels that won’t fade or fall off over time. - Check for Environmental Factors

Avoid installing breakers in locations exposed to excessive vibration, moisture, corrosive chemicals, or temperature extremes unless specifically rated for those conditions.

Testing & Maintenance Best Practices

Circuit breakers should be tested periodically, especially in industrial environments where uptime is critical. Here are the core approaches:

Manual Trip Testing

Use the breaker’s built-in test button (if available) to simulate a fault and ensure the mechanism responds appropriately. This is especially important in GFCIs, AFCIs, and digital MCCBs.

Insulation Resistance Testing

Performed between terminals and ground using a megohmmeter. This ensures insulation integrity and detects internal degradation.

Contact Resistance Testing

Helps identify pitting or wear on contacts that can lead to voltage drops and heat buildup. Typically performed in medium and high-voltage breakers.

Thermal Imaging

Use infrared cameras during operation to identify hot spots, loose connections, or load imbalances—often before they result in failure.

Trip Curve Validation

Compare real-world trip times with the breaker’s published time-current curves. Deviations may indicate calibration drift, requiring adjustment or replacement.

Visual Inspection & Cleaning

Inspect enclosures, terminals, and mechanical linkages. Dust, corrosion, or foreign objects can impair functionality. Clean with non-conductive solvents and follow lockout/tagout procedures during service.

Testing Frequency Recommendations

Testing frequency depends on the type of breaker and its operational environment. For most Miniature and Molded Case Circuit Breakers (MCBs/MCCBs), an annual test schedule is typically sufficient, though high-use applications may require more frequent checks. Air Circuit Breakers (ACBs) and Vacuum Circuit Breakers (VCBs) should generally be tested every one to two years, especially after experiencing any major faults or load shifts. Ground Fault Circuit Interrupters (GFCIs) and Arc Fault Circuit Interrupters (AFCIs) are designed for frequent testing—ideally once a month—using their integrated test buttons. High-voltage SF₆ circuit breakers have more complex requirements and should undergo full inspection and gas pressure testing every three to five years, or sooner if performance indicators suggest degradation.

FAQs About Circuit Breakers

Every industrial project or facility upgrade raises questions, especially when it comes to electrical safety and system design. Here are some of the most frequently asked questions about circuit breakers, answered with the clarity and practicality professionals like you expect.

Why does my circuit breaker keep tripping?

A breaker that trips repeatedly is usually doing its job—protecting your system from an underlying issue. Common causes include overloaded circuits, short circuits, or ground faults. If you’re running multiple high-demand devices on one circuit, or if there’s a wiring fault, the breaker will trip to prevent overheating or fire. In industrial environments, worn motors, faulty VFDs, or improper breaker sizing can also be culprits. It’s important to diagnose the root cause, not just reset the breaker.

Can I reset a circuit breaker after it trips?

Yes, most circuit breakers are designed to be reset manually after tripping. To do this safely, first turn the breaker completely off, then switch it back on. However, if the breaker trips again immediately or frequently, don’t keep resetting it—this indicates a fault that needs professional attention. Repeated tripping without addressing the cause can lead to equipment damage or fire risk.

How often should I test or replace circuit breakers?

The frequency of testing depends on the breaker type and application. For general use breakers like MCBs and MCCBs, an annual test is a good rule of thumb. GFCIs and AFCIs should be tested monthly using the built-in button. High-voltage breakers may require testing every 3–5 years, including gas integrity checks for SF₆ models. As for replacement, breakers typically last 15–30 years, but factors like environmental conditions, load cycles, and fault exposure can shorten that lifespan. Always follow the manufacturer’s maintenance recommendations.

What’s the difference between a GFCI, AFCI, and standard breaker?

- GFCIs (Ground Fault Circuit Interrupters) are designed to detect small current leaks (as little as 4–6 milliamps) and trip to prevent electrical shock. They’re common in wet or damp locations.

- AFCIs (Arc Fault Circuit Interrupters) detect dangerous electrical arcing—often caused by damaged wires or loose connections—and trip before an arc can ignite a fire.

- Standard breakers protect primarily against overloads and short circuits but won’t detect ground faults or arc faults. In modern systems, all three types may be required to meet code and provide full-spectrum protection.

Can I use the same breaker for AC and DC circuits?

No—AC and DC breakers are built differently to handle how current flows and how arcs are extinguished. AC arcs naturally extinguish at zero-crossing points in the waveform, while DC arcs do not, requiring faster mechanical or magnetic arc suppression. Using an AC breaker on a DC circuit is not only dangerous but also often a code violation. Always check the breaker’s rating label—some models are dual-rated, but most are not.

What should I do if a breaker is warm or hot to the touch?

A breaker that’s warm under load can be normal, but excessive heat is a red flag. It could indicate an overloaded circuit, a loose terminal, or a failing breaker. In high-load panels or older systems, thermal buildup can lead to nuisance tripping or even component failure. Use infrared thermography to check for hot spots and consult your supplier or service provider if temperatures are above acceptable thresholds.

Got more questions specific to your project or facility? Our team at Electrical Power and Control is always ready to help you troubleshoot, spec, or source the right breaker, without the guesswork.

Conclusion

In industrial and commercial environments, circuit breakers aren’t just components—they are the frontline defense against costly failures, safety hazards, and unplanned downtime. From panelboards to large-scale switchgear, every electrical system relies on the proper use of circuit breakers to function safely and efficiently.

By understanding how circuit breakers operate, the different classifications available, where they’re used, and how to choose and maintain them, professionals like you can make smarter decisions that lead to more reliable systems and more confident operations. Whether you’re specifying protection for a new build, retrofitting an aging panel, or supporting preventive maintenance in a facility, knowing what to look for in a breaker can save time, reduce risk, and keep your operations running smoothly.

As the industry continues to shift toward smarter, greener, and more responsive systems, the role of the circuit breaker continues to evolve, becoming more than just a trip mechanism. Today’s circuit breakers support remote monitoring, contribute to arc flash mitigation strategies, and integrate seamlessly with smart grid and industrial automation systems. In other words, your breakers are now just as strategic as they are protective.

At Electrical Power and Control, we understand that choosing the right circuit breaker isn’t always straightforward. With hundreds of configurations, standards to consider, and growing environmental demands, the right solution needs to be both code-compliant and tailored to your operational goals.

If you need any type of circuit breaker for your industry—whether it’s for a manufacturing plant, commercial building, system integration project, or specialty application—we’re ready to help. Call us today at (205) 812-5402 to speak with our knowledgeable team. You’ll get more than a product—you’ll get a partner who’s committed to your success.