Table of Contents

ToggleIn today’s industrial landscape, energy efficiency isn’t just a goal—it’s a requirement. From rising utility costs to increasing pressure for sustainable operations, every component in an electrical system plays a role in reducing waste and improving performance. One of the most overlooked contributors? Industrial air breakers.

These critical devices do more than just interrupt current during faults—they help protect systems from costly energy losses, equipment damage, and unplanned downtime. When properly selected and maintained, they can enhance system reliability while supporting larger energy-saving strategies. Yet, many operations don’t fully understand how these breakers work—or how much they can save over time.

This article breaks down how air breaker parts work, what makes them unique, and why they’re a smart investment for any energy-conscious facility.

What Are Industrial Air Breakers?

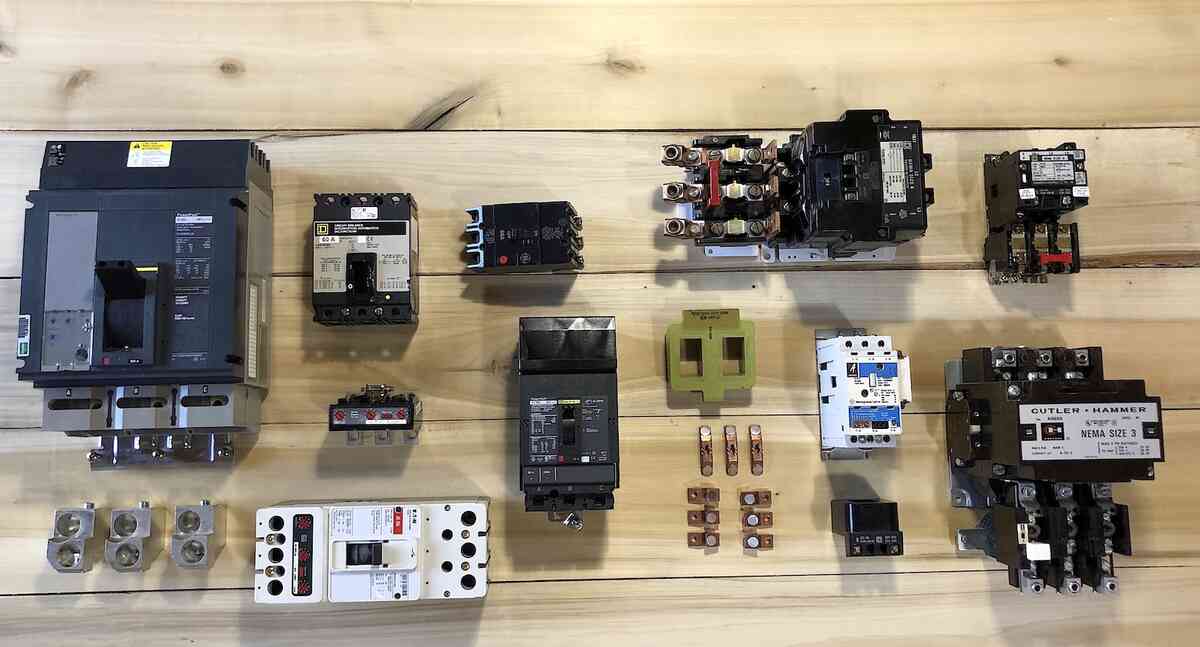

Industrial air breakers are large-scale electrical protection devices designed to interrupt high current flow during faults. Commonly used in facilities like manufacturing plants, data centers, utilities, and processing operations, these breakers don’t just prevent damage—they play a crucial role in maintaining system efficiency, uptime, and safety.

Unlike standard breakers found in residential or small commercial panels, industrial air breakers are engineered to manage complex, high-load environments. They’re built to interrupt massive electrical currents safely and reliably, using air—not oil or gas—as the medium to extinguish arcs during fault conditions.

Let’s break that down further.

Why Air? The Role of Arc Quenching

Every time a breaker trips, an electrical arc is formed between its contacts. In air breakers, this arc is cooled and broken up using air and a metal arc chute. These arc chutes divide the arc into smaller sections, which are easier to extinguish quickly. The faster the arc is quenched, the less energy is wasted and the safer your system remains.

Air is an effective arc-quenching medium in open environments where frequent breaker access, easy maintenance, and system flexibility are needed.

Where Industrial Air Breakers Are Used

You’ll typically find industrial air breakers in:

- Motor control centers (MCCs)

- Switchgear and panelboards

- Utility substations

- Large-scale manufacturing or process facilities

They’re ideal for these settings because they:

- Handle higher voltage and amperage than molded case breakers

- Support adjustable trip settings for energy-conscious operations

- Can be reused and maintained instead of being replaced after tripping

Bottom line? Industrial air breakers are more than just safety gear—they’re smart, strategic assets in any efficient power system.

How Air Breaker Parts Work to Optimize System Performance

Understanding how air breaker parts work is key to realizing their full value—not just as protection devices, but as tools for improving efficiency and minimizing energy loss across your facility.

Each part inside an industrial air breaker plays a role in ensuring reliable operation, fast fault interruption, and overall system performance. Let’s take a closer look.

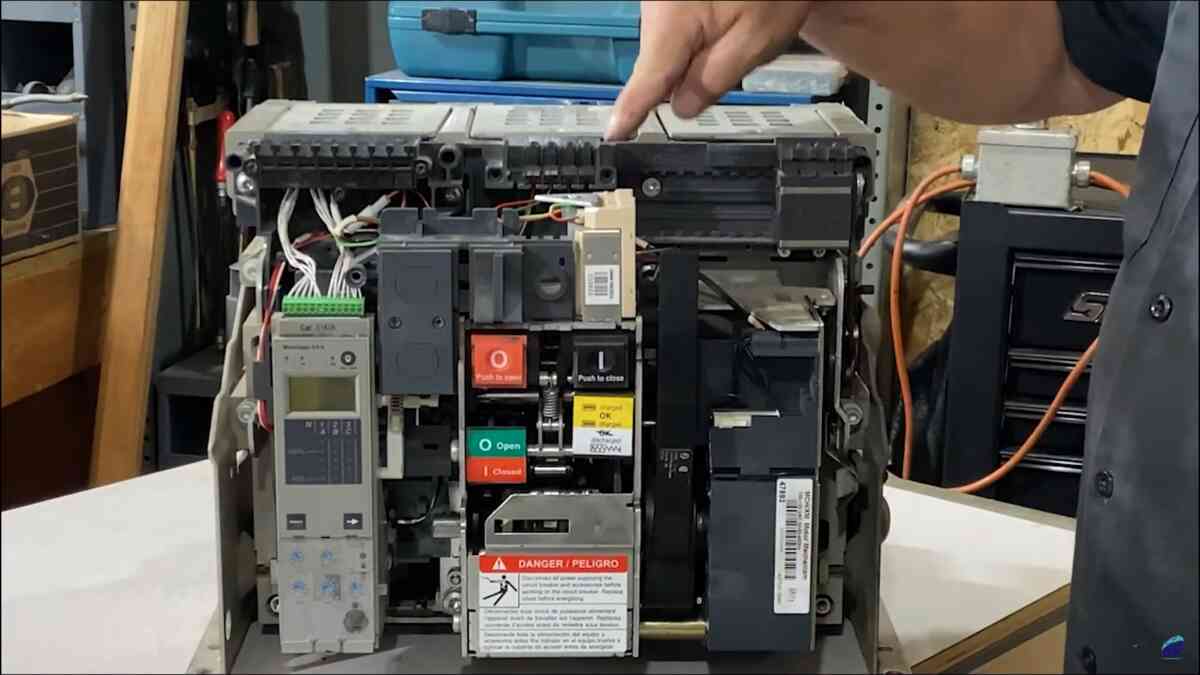

Core Components of Industrial Air Breakers

- Arc Chute

When a fault occurs, an arc forms between the contacts. The arc chute—made of layered metal plates—splits and cools the arc, allowing it to extinguish quickly. This reduces the time and energy wasted in the form of heat and light. - Contacts

These are the conducting parts that open and close the circuit. Good contact alignment ensures minimal resistance during normal operation and safe separation during a fault. - Trip Unit

The trip unit monitors current flow and initiates the breaker operation if an overload or short circuit is detected. Advanced versions offer adjustable settings, enabling precise protection and helping avoid nuisance trips that waste energy and time. - Operating Mechanism

This includes the spring or motor-charged systems that physically open the contacts when a trip signal is sent. A well-maintained mechanism ensures fast and consistent response, reducing downtime and energy loss.

How These Parts Improve Efficiency

- Faster Arc Interruption: Reduces energy waste during faults

- Customizable Protection Settings: Prevents unnecessary shutdowns

- Long-Term Durability: Minimizes replacement needs and lifecycle energy cost

- Ease of Maintenance: Regular inspection of parts can extend service life and optimize performance

Together, these components make industrial air breakers not just reactive safety tools, but proactive contributors to energy-efficient operations.

The Link Between Air Circuit Breakers and Energy Efficiency

It’s easy to think of circuit breakers only as emergency protection devices. But air circuit breaker energy efficiency is more than a technical bonus—it’s a functional advantage that plays out every day in industrial facilities.

These breakers don’t just stop current. They help control it. And in doing so, they reduce waste, optimize load distribution, and support smarter power management over time.

Fast Fault Clearing = Less Energy Waste

When a fault occurs—whether it’s a short circuit or an overload—every second counts. The longer it takes to interrupt that current, the more heat is generated, and the more strain is placed on connected equipment. Industrial air breakers, especially those with well-calibrated trip units and maintained arc chutes, interrupt faults almost instantly.

Those speed limits:

- Energy lost as heat

- Unnecessary power draw

- Downstream equipment stress

The result? A more stable, less wasteful electrical system.

Adjustable Trip Settings for Smarter Load Management

One of the biggest energy-saving advantages of air circuit breakers lies in their adjustable protection settings. Facilities can fine-tune these settings to match actual load demands, avoiding oversized protection that leads to inefficiencies.

Benefits include:

- Reduced nuisance trips that interrupt operations

- Targeted fault protection that prevents full-system shutdown

- Better alignment between load capacity and breaker response

This means your system doesn’t just stay safe—it runs smarter.

The Cumulative Effect on Energy Efficiency

Individually, these efficiency gains may seem small. But over time—and across large facilities with multiple breakers—they add up to:

- Lower overall energy consumption

- Fewer unplanned outages

- Longer equipment lifespan

In industries where margins matter and downtime costs thousands per minute, these improvements are both technical and financial wins.

Smart Innovations in Air Breaker Technology

As industries push for higher efficiency and smarter operations, industrial air breaker parts are evolving to keep pace. Modern air circuit breakers aren’t just mechanical—they’re intelligent. And these advancements are turning traditional protection devices into dynamic tools for energy management.

Let’s explore the innovations that are reshaping how breakers contribute to performance and savings.

Intelligent Trip Units and Energy Monitoring

Traditional trip units do one job: detect a problem and trip the breaker. But smart trip units go further.

They now offer features like:

- Real-time current monitoring

- Energy consumption tracking

- Customizable protection profiles

- Communication with building management systems (BMS)

These capabilities give maintenance teams visibility into how breakers behave under different loads, helping them optimize energy use, prevent overloads, and plan for peak demand periods.

Remote Diagnostics and Predictive Maintenance

With integrated sensors and communication modules, smart air breakers can alert teams before problems escalate. Think:

- Email or dashboard alerts when trip thresholds are nearing

- Data logging for historical analysis

- Predictive maintenance recommendations based on usage patterns

Instead of reacting to failures, facilities can stay one step ahead—minimizing costly downtime and energy waste.

Integration with Smart Grid and IoT Systems

In advanced setups, industrial air breakers can now be part of broader energy strategies:

- Load shedding in response to grid demand

- Automated system responses during voltage drops or spikes

- Coordination with solar or backup systems for efficient transitions

These aren’t just “breaker upgrades”—they’re infrastructure improvements that support modern, efficient energy systems.

Bottom line? Smart air breaker technology isn’t just for high-tech facilities anymore. It’s becoming essential for any operation serious about efficiency, uptime, and long-term cost control.

Maintenance Tips to Maximize Efficiency Over Time

Even the most advanced industrial air breakers can lose their efficiency edge without proper maintenance. Over time, dust, oxidation, mechanical fatigue, and unnoticed calibration drift can turn energy-saving equipment into energy-wasting liabilities.

That’s why routine inspection and upkeep are non-negotiable—not only for safety compliance but also for operational efficiency.

Let’s break down the key areas to focus on for long-term breaker performance.

Arc Chute Maintenance: Keep the Heart of the Breaker Clean

The arc chute plays a critical role in extinguishing electrical arcs during a trip event. A dirty or degraded chute reduces the breaker’s ability to dissipate heat quickly—leading to longer arc durations, increased energy loss, and even fire risks.

Maintenance Tips:

- Inspect quarterly for soot buildup, corrosion, or warping

- Use compressed air or a vacuum (not high-pressure water or solvents) to remove fine dust and debris

- Replace arc chutes showing visible pitting, discoloration, or damage from previous interruptions

- Check alignment and secure mounting of arc splitters and plates

Failing to maintain this component can reduce your system’s ability to break faults efficiently, costing more in downtime and energy waste.

Trip Unit Testing and Calibration: Precision Prevents Problems

Trip units are the brains of your air breaker—they monitor current, detect faults, and trigger disconnection. Over time, these devices can become misaligned due to vibration, heat exposure, or internal degradation.

Maintenance Tips:

- Perform annual testing using a secondary injection test set or breaker test kit

- Validate time-current curve accuracy against original settings or protection requirements

- Recalibrate the settings if your facility’s load profile has changed (especially after expansions or equipment upgrades)

- For smart trip units, download event logs and usage data to analyze breaker behavior and identify trends

Proper calibration ensures your breaker trips only when necessary—protecting both uptime and energy integrity.

Contact and Mechanical System Care: Reduce Resistance and Failure Risks

The contacts inside a breaker are where the actual disconnection happens. If these are worn, pitted, or misaligned, resistance increases—creating excessive heat and voltage drops across your system.

Maintenance Tips:

- Inspect for burn marks, pitting, oxidation, or uneven wear

- Use a micrometer to measure contact thickness against OEM standards

- Clean lightly oxidized contacts with an approved contact cleaner (avoid abrasives that damage silver coatings)

- Ensure the operating mechanism engages smoothly and quickly—a slow or sticking trip can extend arc time and increase energy waste

Lubricate mechanical linkages as recommended by the manufacturer, and test the spring charging mechanism for fatigue or delay.

Build a Preventive Maintenance Schedule Around Load Cycles

Not every facility needs the same maintenance frequency. A food plant running 24/7 has different stress points than a seasonal packaging facility. Maintenance schedules should reflect real-world load and environmental conditions.

Best Practices:

- Use infrared thermography during live operation to detect hot spots or loose connections

- Implement contact resistance testing annually to catch degradation early

- Record and trend breaker performance data over time to anticipate future repairs

- Align breaker maintenance with other scheduled electrical inspections (like transformer or panel testing)

A proactive plan helps avoid reactive service calls—protecting both budgets and uptime.

Partner With Experts for Long-Term Reliability

You don’t have to manage this alone. EPC partners with facility managers and electrical contractors to:

- Perform field testing and diagnostics

- Source replacement air breaker parts quickly

- Offer expert consultation on trip unit settings and performance optimization

- Help you stay compliant with NEC/NFPA 70 and OSHA standards

Regular maintenance isn’t just a checkbox—it’s a long-term investment in energy efficiency, safety, and peace of mind.

Conclusion:

In a world where energy efficiency is tied to profitability, sustainability, and operational resilience, the role of industrial air breakers goes far beyond fault protection. They’re essential tools for managing energy intelligently, reducing waste, and optimizing system performance.

When you understand how air breaker parts work—from the arc chute to the trip unit—you start to see how small design choices translate into big operational gains. Add in smart monitoring, customizable settings, and a preventive maintenance plan, and you’ve got more than a safety device—you’ve got a long-term strategy for energy efficiency.

Whether you’re modernizing a facility, managing aging infrastructure, or just trying to reduce downtime, air circuit breaker energy efficiency should be part of the conversation.

If you need help choosing the right breaker or want expert advice on keeping your system running at its best, call Electrical Power and Control at 205-463-5260. We’re here to help you minimize downtime, maximize performance, and make smart energy decisions—every step of the way.